The rocket stove can be made independently using ordinary steel. The rocket stove is widely known throughout as a long-burning solid fuel heating structure. To achieve maximum efficiency, I had to work hard. A liquid fuel stove is capable of giving up all its energy, but wood is more difficult to process. To reveal the full potential of wood, a chamber for post-combustion of gases was equipped in jet furnaces.

The principle of operation of the long-burning rocket furnace

The Shirokov-Khramtsov rocket or jet furnace got its name not because of its connection with space. The point is in the shape of the device and the noise that is created during operation, reminiscent of the operation of a rocket. But this sound indicates that the oven is being used incorrectly.

Types of long burning rocket furnaces:

- Portable (mobile);

- Stationary (for heating).

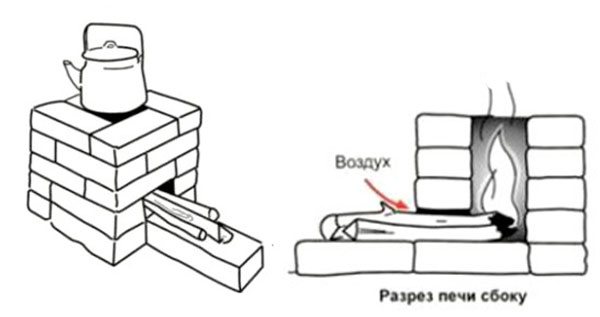

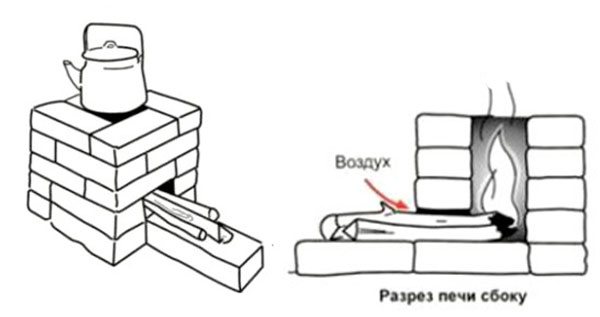

The most popular rocket model is the Robinson. It is often used on hikes. Thanks to the small portable apparatus, you can understand the principle of operation of the jet furnaces. The shape of the oven resembles the letter "L".

If the stove makes too much noise and hums during operation, then such a mode is ineffective and expensive. Normally, there should be a quiet sound, a little rustling.

The reactive furnace has a receiving hopper. This is the horizontal part of the pipe. In the channel itself, a thrust arises, it is this that affects the intensity of combustion, which heats the body. That is why it is advised to limit the supply of oxygen. Otherwise, the wood will quickly burn out and all the heat will evaporate.

A long-burning rocket furnace is often used to heat garages and utility rooms.

The furnace is powered by a jet draft due to the natural flow of hot air. The higher the temperature of the furnace walls, the better the wood burns. This allows you to quickly heat water in a large container, which is indispensable for a road trip. If you equip the pipe with thermal insulation, then after warming up, you can burn thick logs.

DIY making

A home-made stove from a waste gas cylinder is an affordable option for a wood-burning stove, which is designed for efficient space heating and economical fuel consumption.

To make a stove at home, you will need:

- Empty cylinder body - 2 pcs.

- Metal pipe for creating a vertical chimney (diameter - 12 cm).

- Profile pipe for the manufacture of a firebox and a loading chamber (length 100 cm, section - 12 × 12 cm).

- Cuts of metal pipes: short by 80 cm (diameter - 15 cm) and long by 150 cm (diameter - 12 cm).

- Steel sheet (thickness 3 mm).

- Metal rods.

- Heat-insulating material (perlite).

- Welding equipment.

- Bulgarian.

- Personal protective equipment - glasses and gloves.

To ensure correct assembly of the oven, it is recommended to prepare a working drawing indicating the exact dimensions of all structural elements of the device.

Step-by-step instructions for making a rocket furnace:

- Three sections are cut from the profile pipe - two of them are 30 cm each and one for the lounger by 35 cm. From the blank for the lounger, the grinder makes a rectangular hole for the fuel compartment and a semicircle for the vertical pipe.

- One 30cm billet is cut longitudinally and welded to the fuel compartment to create an air channel.

- The fuel compartment is hot-welded to the pipe.

- A grate is made of fittings, doors for the fuel chamber and ash pan.

- Next, a secondary chamber is made for the afterburning of pyrolysis gases.

- A hole is made at the bottom of the cylinder for the fuel compartment.On the outside of the cylinder, a knee is fixed under a pipe with a diameter of 12 cm for the chimney.

- A hole is cut at the bottom of the pipe to clean the chimney.

- A pipe section with a diameter of 15 cm is placed on top of the pipe and welded to the cylinder by welding.

- The free space between the two pipes is filled with insulation, the edges are closed with a welded seam.

- In the second cylinder, the bottom is cut off and a hole for the valve is welded. It will be used for the afterburning of pyrolysis gases.

- Both cylinders are fixed to each other in a special groove using two welded rings so as to ensure the tightness of the finished structure. The groove is sealed with an asbestos cord.

Important! Before proceeding with the firebox of a homemade rocket furnace, it is necessary to carefully check the quality of the joints and the tightness of the structure. Air masses must not penetrate into the operating unit uncontrollably.

Do-it-yourself rocket furnace: advantages, drawings, disadvantages

The conventional furnace design can be improved if desired. So the potbelly stove loses a lot of heat, but by equipping the device with a water circuit or brickwork, you can solve these problems. For all these manipulations, drawings are made.

Advantages of jet furnaces:

- Simple and budget-friendly design. You can use materials at hand, without significant financial costs. All work can be done by hand, special knowledge and skills are not required.

- You can independently control the combustion by choosing the desired intensity.

- High efficiency. In general, it all depends on the quality of the installation. The main thing is to take the maximum energy from the flue gases.

But such a simple and convenient design also has significant drawbacks. So you need to select a special fuel for the stove. Do not use damp wood, otherwise pyrolysis will not occur. The firebox may start to smoke profusely, and all gases will go into the house. In addition, the rocket furnace requires increased safety requirements.

The most popular portable model is the Robinson rocket furnace. It was modified and a grate was added.

Homemade jet ovens are not used to heat the bath. They are ineffective in infrared light, which plays an important role in the steam room. Surface structures have a small heating area, so they cannot heat the bath.

Brick rocket furnace

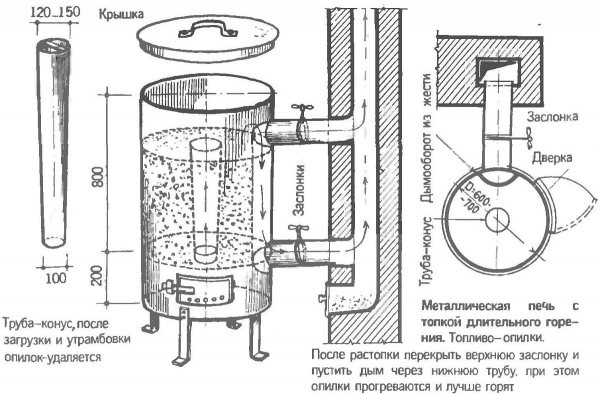

Making a brick oven is not much different from a metal one, but it will require more material investments. The entire structure, except for the cap, must be lowered below the floor level, for this it is necessary to dig a hole and compact its bottom.

Recommended: How to make a grill smokehouse?

After finishing the manufacture of the stove, the pit should be filled up, and an iron barrel is placed on the bell, cutting off the bottom of it. Metal or brick rocket ovens are equally effective and it all depends on your desire and home design.

Drawings of a jet furnace from a gas cylinder and other types

Long burning stoves are divided into stationary and mobile. Mobile ovens are used in hikes, picnics, in nature for heating and cooking. Stationary ones are used to heat a house, outbuildings, greenhouses, and a garage. At the same time, 4 types of structures are distinguished.

Types of jet furnaces:

- Homemade camping stove made of metal pipes, buckets, cans;

- Reactive design from a gas cylinder;

- Brick oven with a metal container;

- Stove with a stove bench.

Drawings of a jet furnace from a gas cylinder can be downloaded on the Internet or made by hand

The portable structure is equipped with pipe sections. The only difference concerns the installed ash pan. For the lower part, a grate can be used.

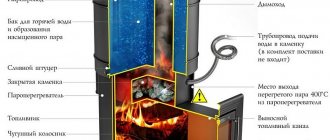

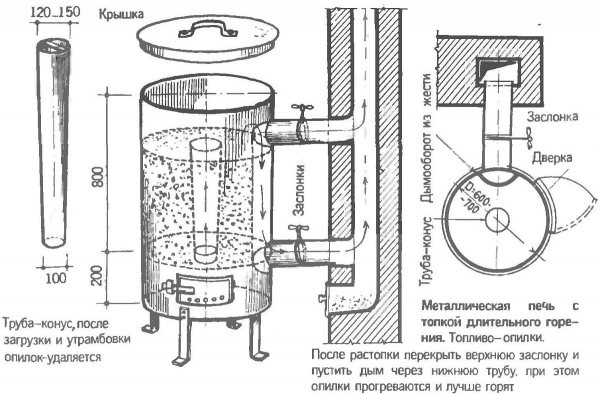

A device from a gas cylinder is more difficult to build, but it significantly increases efficiency. For the installation of the structure, a barrel or gas cylinder is required.The firewood in the firebox burns due to the oxygen inflow by loading through a special window.

Gases burn out in the pipe, which is located inside the structure, due to the supply of secondary air. The effect is enhanced by insulating the inner chamber. Hot air is placed in the hood, and then into the outer chamber. The combustion products are removed through the chimney.

To create a draft, the top of the chimney is placed 4 cm above the loading window.

The combined brick and metal model is a stationary structure. Due to its high heat capacity, the wood-burning stove stores and releases heat for several hours. That is why living quarters are heated with such a design.

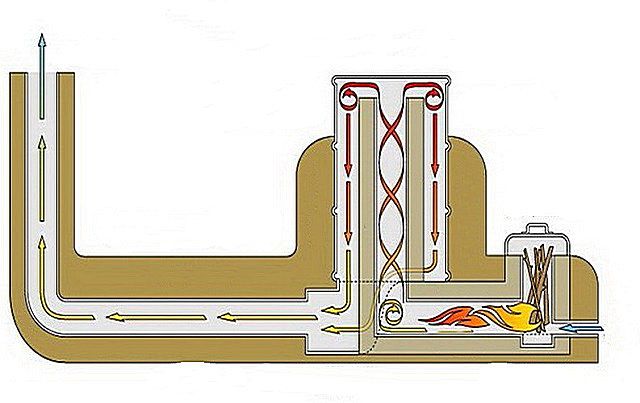

The rocket unit with a stove bench is an improved device that is able to retain heat for longer. Since some of the heat comes out through the chimney, its length was increased. Due to the rapid excision of hot gases and a larger chimney, this problem was solved.

This is how massive stoves with a stove bench are obtained, which are similar to a sofa or bed. These are stationary devices made of brick or stone. Thanks to its unique design, the stove is able to retain heat throughout the night.

Principle of operation

During the thermal decomposition of solid organic fuel, gaseous substances are released, which also decompose and turn into wood gas in the process, which has a high level of heat transfer during combustion.

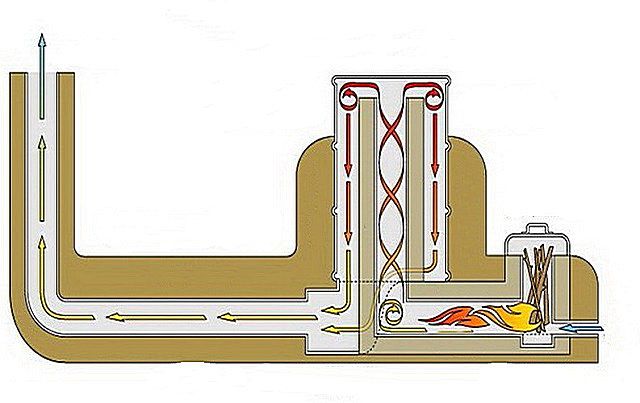

In conventional solid fuel stoves, wood gas goes into the pipe along with the gas, where it cools down and settles on the walls in the form of soot. In a rocket-type furnace, due to the horizontal channel, the gases move more slowly, do not have time to cool down, but burn out, giving off a large amount of heat.

In models of jet heating devices of complex design, heated air and gas flows through a series of internal channels. Then they move to the upper part of the body, under the hob, where it burns completely. For such a rocket, there is no need for additional inflation. The draft in them is created at the expense of the chimney, and the longer its length, the more intense the ascending flow.

Principle of operation

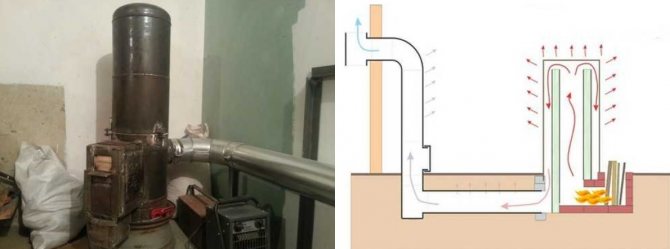

In this diagram, the principle of operation of a rocket oven with a stove bench

Diy drawings of the Ognivo stove and other models

It is best to make small portable structures with your own hands: the Ognivo and Robinson rocket. It is easy to perform the calculation, and the work will require trimming shaped pipes and metal welding skills. The dimensions may differ from the drawing, this is not a problem. It is important to respect the proportions.

To increase the intensity of combustion, it is advised to add improvised nozzles to the structure. Secondary combustion air will be supplied there.

Stationary rocket ovens are made from a gas cylinder or metal barrel. These elements serve as a body. Inside, the stove is equipped with smaller pipes or fireclay bricks. From a cylinder, you can make both a stationary unit and a mobile one.

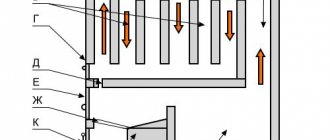

Continuous combustion furnace diagram:

- Chimney;

- Cap;

- Insulation;

- Loading hopper;

- Combustion zone;

- Afterburning zone.

The Ognevo stove can be bought in a specialized store at a fairly reasonable price.

It can be difficult to calculate a rocket furnace, because there is no exact method. You should pay attention to checked ready-made drawings. It is necessary to determine the size of the heating equipment for a particular room.

How does the heater work?

There are 2 reasons for the appearance of the characteristic name: a specific hum, emitted when fuel is burned, and the uncomplicated form of the unit, reminiscent of an inverted child's drawing of a rocket.

It is noteworthy that the hum during the firebox indicates an irrational, ineffective combustion mode, it is better if the stove emits a quiet, even rustle. You can find the extended name of such a unit - the Shirokov-Khramtsov rocket furnace.

The equipment can be portable and stationary. The simplest mobile modifications were developed for field conditions, they are adapted for cooking, heating water.

A more productive stationary long-burning rocket stove is equipped with a special hood, thanks to which the heat from the smoke is directed into the room. At the start, air is supplied in a limited amount; when fuel is burned, pyrolysis gases are formed. In the lower part of the vertical pipe segment, they are burned out: secondary air enters here through a separate channel.

The combustion products, which have a high temperature, rise to the bell, gradually cool down, descend between the walls and pass into the chimney. They are affected by the natural traction force in this channel, new gases coming from the firebox, and gravity are influencing. In order to collect as much heat as possible and direct it to heating the room, smoke channels of an intricate configuration are attached to the stove - they are laid in the base of the bed.

Assembling a jet furnace with your own hands for heating

The construction of the furnace begins with preparatory work. First you need to decide on the place of construction. It is chosen based on the requirements that relate to solid fuel structures: wood or coal.

When the place has been decided, it is necessary to properly prepare it for construction. The wooden floor under the stove is being dismantled. They dig a small pit and tamp the bottom.

In a small room, a jet oven is placed in the corner. The loading hopper occupies one side and the lounger the other.

The barrel or cylinder must also be prepared for installation. To do this, cut off the lid and the tap from them. Then the structure is cleaned. Next, a solution is prepared.

Stages of construction of a jet furnace with a stove bench:

- The bottom of the dug hole is laid out with fireclay bricks. Formwork is made along the contour of the recess. Reinforcement is performed.

- The base is laid out and poured with concrete. A day later, when the concrete hardens, further work begins.

- The base of the stove is laid out of fireclay bricks. Raise the side walls, make the lower channel.

- The combustion chamber is covered with bricks. There are two holes on the sides. One is for the firebox, the second is for the vertical pipe (riser).

- The metal body is equipped with a flange into which the horizontal channel of the stove will flow. All cables must be airtight and well sealed.

- A side outlet is attached to the horizontal pipe, which serves as an ash pan.

- A fire tube is made of bricks. As a rule, it is square.

- The flame tube is equipped with a casing. The gaps are covered with perlite.

- The assembly of the cap is done from the cut off part of the barrel or cylinder. It is equipped with a handle.

- Equip the furnace body with brick or stone.

- Equip the front of the oven. Lay out the required contour.

- A prepared barrel is placed on the base. The lower part must be sealed with clay.

- With the help of a corrugated pipe, a channel is formed that connects the firebox with the street.

- The heat exchanger pipes are connected to the lower pipe.

- Install a chimney. All elements must be sealed using asbestos cord and refractory coating.

To properly assemble a jet furnace with your own hands, you should first watch the training video and study the recommendations of specialists

Next, you should give the stove the shape of a couch. The external chimney is equipped with a fire and tar trap. When all materials are dry, the design can be tested.

Operating tips

It is only necessary to launch a brick rocket furnace with a warm chimney. For a small device, this property is not so important, and a larger stove for a cold pipe only uses firewood in vain.

Therefore, before loading the fuel rate after a long break in operation, the rocket must be heated with paper, dry shavings, straw, etc., placing them in a blower with an open door.When the hum in the stove lowers the tonality or dies down, then you can load all the fuel into the furnace, it should ignite by itself from the already existing fire.

A rocket stove with a stove bench is not a fully self-regulating device for external conditions and fuel energy efficiency. Therefore, at the beginning of the firebox with the standard amount of fuel, the blower door is left in the open position. After the stove starts humming strongly, it is closed to a position where the sound made is barely audible.

Only dry wood can be used to warm up the stove, wet wood will not allow the stove to warm up to the desired temperature, which can lead to back draft.

Improved rocket furnace with water circuit

A long burning boiler can be obtained by equipping the stove with a water jacket. Heating water may not be effective enough. The fact is that the bulk of the warm air enters the room and containers on the hobs. To create a rocket cauldron, you must give up the possibility of cooking on the stove.

Materials required for equipping a stove with a water circuit:

- Fireclay bricks and mortar;

- Steel pipe (diameter 7 cm);

- Barrel or cylinder;

- Insulation;

- Sheet steel and a barrel with a smaller diameter than the hull to create a water jacket;

- Chimney (diameter 10 cm);

- Details for the heat accumulator (tank, pipes, connecting pipe).

A characteristic feature of rocket furnaces with a water circuit is that the insulation of the vertical part ensures the combustion of pyrolysis gases. In this case, warm air is directed into a coil with a water circuit and gives off heat to the stove. Even when all the fuel has burned out, warm air will still be supplied to the heating circuit.

Rocket furnace design options

If you need to assemble a rocket oven with your own hands, you should use the drawing of the portable model "Robinson", it is constructed from scraps of a profile pipe and a metal support on legs. All work is reduced to welding. The schemes are quite variable, they allow the use of pipes of a different section, in this case all parameters must be adjusted to the proportions.

For the manufacture of large heating units, a 200-liter metal barrel or a gas cylinder is used. An outer cap is formed from these elements; fireclay bricks or pipes of medium diameter are used to assemble the internal parts. If you take a gas cylinder as a basis, you can get at the exit both a mobile structure and a full-fledged stationary device with a stove bench.

The most difficult stage before assembly is the calculation of the thermal power of the device. Craftsmen recommend using ready-made drawings indicating the source materials; when choosing a scheme, you need to compare the potential dimensions of the furnace and the heated area.

To increase the efficiency of the furnaces, modifications have been developed that are capable of targeted heat collection:

- oven-stove,

- with a water circuit,

- with a couch.

The first type is equipped with an extended hob, on which several containers can be used at the same time. A vertical pipe with a firebox and a door is located directly under the stove, under which there is also a horizontal channel. Hot air heats the hob both directly and through the duct. The outdoor model has stable legs that ensure the reliability and safety of the structure.

The rocket oven can be equipped with a hob

The stove with a water circuit is mounted on a concrete base to prevent distortions. The fire channel and the furnace compartment, lined with bricks, form the lower part, and an ash pan is also provided here (firewood is loaded vertically). The steel pipe in the form of a vertical channel is provided with thermal insulation and an outer casing. On the latter, a heat exchanger with a water jacket is fixed.

The model with a couch is quite massive, the extension looks like a sofa or bed. If you wish, you can put a mattress here and use the platform as an extra bed. The bed is laid out of stones combined with a clay mass, or bricks.