The difference between Viadrus boilers

Modern solid fuel boilers Viadrus are popular heating devices. Their installation does not require the consent of certain services. As in the case of other solid fuel units, in order to install a boiler of this brand, you will need to equip a boiler room and a fuel storage room.

The main advantages of Czech boilers are as follows:

- High efficiency.

- Very easy maintenance.

- Long service life.

To ensure stable operation of the device for many years, it is required to clean the combustion chamber from ash and soot twice a week and carry out full maintenance at the beginning and end of the heating season.

Using Viadrus U22 D

Viadrus U22 boiler equipment is successfully used in closed-type heating systems in which forced circulation of the heat carrier is used. It is best to supplement them with devices that protect the boiler from overload.

They can also be mounted in closed systems using heat accumulators and forced circulation. Another use case is gravity systems. Moreover, in this case, the boiler will be able to work not only in closed, but also in open systems. Viadrus U22 perfectly fulfills the function of the main or backup heating equipment.

To change the type of fuel used by preparing the boiler for gas or liquid fuel operation, some design changes will be required. The upgrade will include the replacement of the boiler door, the installation of additional parts of the heat exchanger.

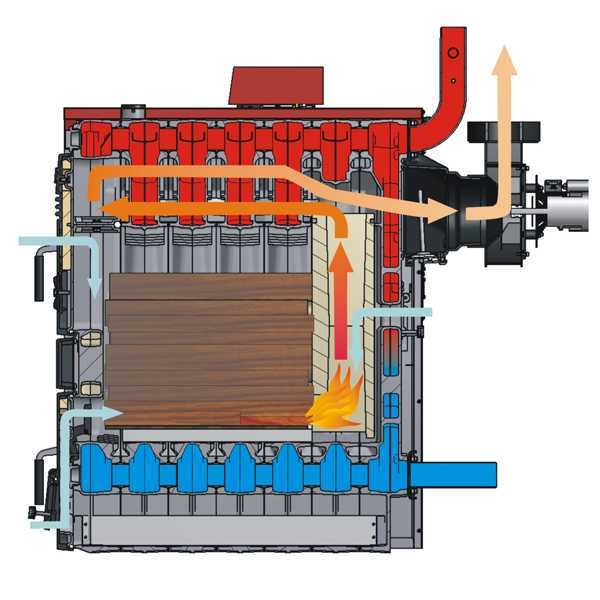

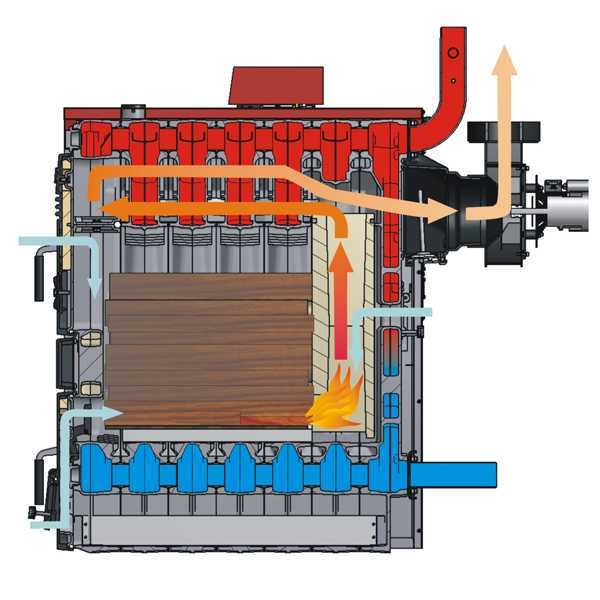

Principle of operation

The Viadrus solid fuel boiler takes wood, coke or coal as fuel. The model range includes pellet boilers with automatic fuel supply. This type of heating unit is the most convenient, therefore it does not require much attention from the owner.

Any type of fuel is loaded into the firebox, then the lid is hermetically closed. This minimizes heat loss and improves the efficiency of the equipment.

The principle of operation of the Viadrus boiler

Experts recommend using coke with a grain size of 40-60 mm as fuel, while the manufacturer guarantees efficient operation on the following types of fuel:

- Walnut 1. Fuel (coke or anthracite) with a fraction of up to 40 mm.

- Walnut 2. The size of non-caking coal fractions is up to 50 mm.

Detailed information on the types of coal and its characteristics can be found here.

Take note that if the chimney draft is good (that is, at least 20 Pa), then lump coal with a grain size of up to 80 mm can be used.

Almost all models also take firewood as fuel. It is important to use only dry logs with a maximum moisture content of 20%. If this figure is higher, then it is quite possible that the efficiency of the boiler will decrease. It is possible to use firewood with a diameter of up to 100 mm, the length is chosen based on the dimensions of the combustion chamber.

According to the instructions, the use of the following type of fuel is not prohibited:

- chips;

- sawdust;

- pellet granules.

If you decide to pour wood chips or sawdust in order to melt the device, then it is advised to put firewood on the bottom of the chamber. Thus, you will exclude the falling of small particles into the ash chamber.

When operating automatic pellet boilers, fuel is poured into a special bunker, from where it is supplied autonomously to the combustion chamber.

Operating conditions

Owners of Viadrus solid fuel boilers note the ease of operation of the device. But still, before starting the equipment, you need to read the instructions.

Before starting the Czech boiler:

- Take readings from the thermomanometer and make sure that there is enough fluid in the system.

- Opens the valves that are installed on the system pipes.

- Check the cleanliness of the smoke channels, grate and ash chamber. If there is soot, you need to remove everything.

- The firewood is laid out on the wire rack.

- Open the flap and close the loading doors.

- Fuel is ignited through the fire door.

- Close the firebox door and open the muffler to allow air to flow.

- The main fuel is poured onto the burnt wood, and it is distributed evenly.

- When the flame turns dark red, use a key to open the dampers on the loading doors.

- When the fire turns yellow, the flaps on the doors close.

- After the coolant reaches the required temperature, the volume of incoming air is reduced. With the help of a muffler, the air supply is regulated for the boiler to operate in the specified mode.

- If necessary, fuel is still reported. The time between approaches to the heating unit for filling fuel depends on the type of fuel and the strength of combustion.

Review of the cast iron boiler VIADRUS Hercules U 22 D 4

Overview of a solid fuel heating cast iron boiler on wood and coal VIADRUS Hercules U 22 D 4 (viadrus hercules u 22 d 4)

Viadrus is a leading manufacturer of cast iron boilers and radiators in Central and Eastern Europe. The history of the Viadrus plant dates back to 1888, when the first cast iron radiators were produced. This was the Bohemia model that has been produced up to this time. The VIADRUS brand is widely known in Europe and the CIS countries. Probably one of the best-selling cast iron boilers in Belarus. Although there are not so few brands from which you can choose from us, there is also enough Czech cast iron and cast iron from Turkey at a lower price. The Czech cast iron boiler Viadrus can operate both in closed systems using a circulation pump and in open systems with an open expansion tank.

The Viadrus Hercules U22 series solid fuel cast iron boiler has 7 boilers.

VIADRUS Hercules U 22 D 4 sections VIADRUS Hercules U 22 D 5 sections VIADRUS Hercules U 22 D 6 sections VIADRUS Hercules U 22 D 7 sections VIADRUS Hercules U 22 D 8 sections VIADRUS Hercules U 22 D 9 sections VIADRUS Hercules U 22 D 10 sections

Advantages of the Viadrus solid fuel cast iron boiler

durability of the heat exchanger made of Czech cast iron over the years the proven design of the boiler the possibility of burning wood with high moisture content (20 ~ 25%) low requirements for smoke draft possibility of gravity operation - cooling of the grates with water easy installation of the boiler thanks to threaded flanges the possibility of switching the boiler to gas or liquid fuel

Packaging and equipment of the Viadrus solid fuel cast iron boiler

Boilers are delivered with fully assembled casings, without assembled thermal insulation and cladding. Cladding and insulation are supplied in a cardboard box. Technical documentation and delivery set are enclosed in the boiler furnace (see instructions).

Packing type - wooden pallet - polyethylene - screed with packing tapes.

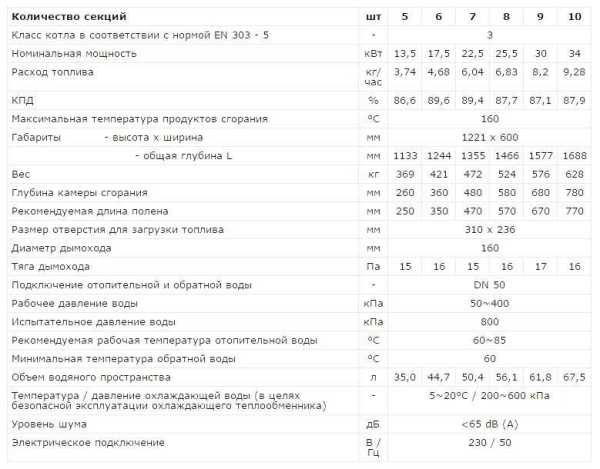

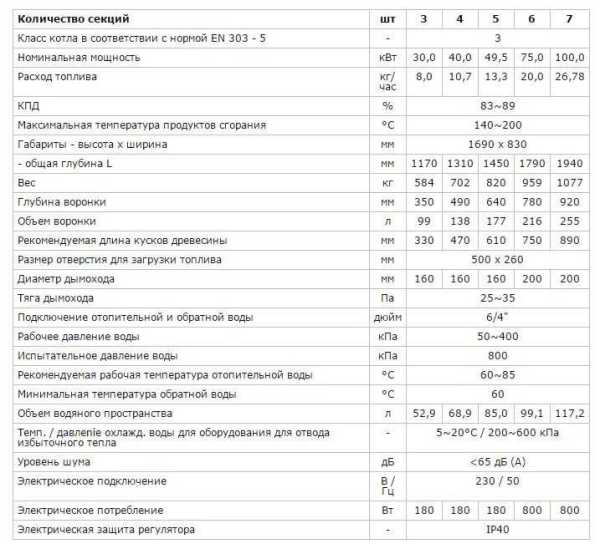

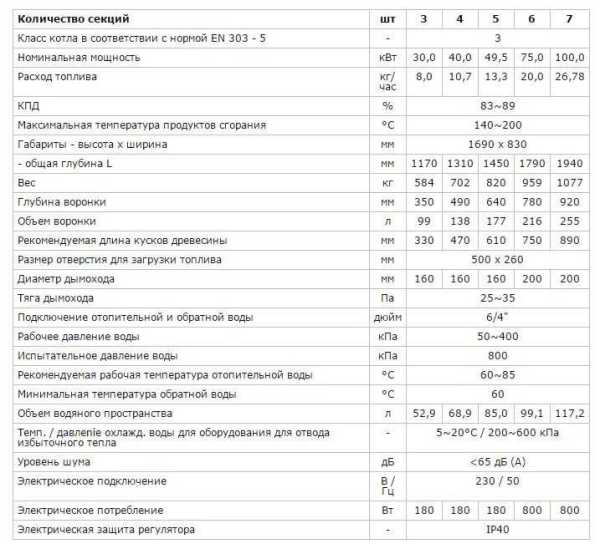

Table of characteristics of the solid fuel cast iron boiler Viadrus

When choosing solid fuel boilers, not only cast iron, but also steel, the consumer makes one very big mistake, most of the values are indicated in the table for the type of fuel coal; There is little coal in Belarus and they usually heat with wood, the boiler is not chosen correctly, because the power when burning firewood will be less and in severe frosts the boiler may not cope. It is better if the calculation of the power of the boilers will be carried out by specialists! (the managers of our store 100kotlov.by will calculate the power of the boilers for you absolutely free)

Below is a table of capacities for coal and wood.

Coal capacity table

Wood power table

Cast iron boiler Viadrus is delivered without packaging, it is delivered separately in a cardboard box. The opening in the ash doors (muffler) regulates the combustion air supply under the boiler grate.

It is controlled by the draft regulator or manually by the adjusting screw on the doors.

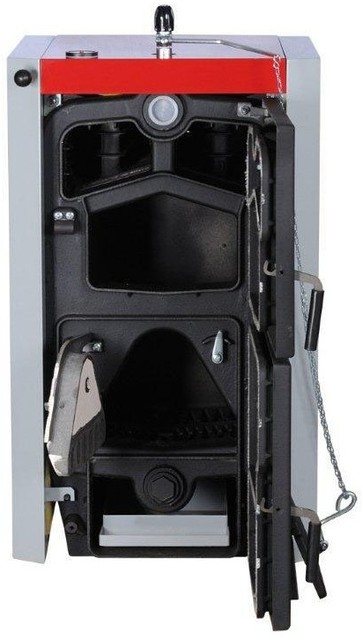

In terms of power, the boiler is very easy to distinguish, even visually, just count the number of sections (in the photo, the Viadrus Hercules boiler is 4 sections)

The chimney damper of the exhaust branch pipe regulates the exit of combustion products from the boiler to the chimney

pipe. Operated by a pull handle in the upper left part of the boiler near the loading doors

The opening in the loading door (rose) serves to supply secondary air to the combustion space. To control the opening, due to the high temperature of the doors, use

a tool that is part of the delivery.

VIADRUS Hercules U 22 cast iron boiler complete set

Cast iron boiler body VIADRUS Hercules U 22

A package of documents for the purchase of the Viadrus boiler

The solid fuel cast iron boiler VIADRUS Hercules U 22 D (Viadrus Hercules u 22 d) can be viewed, bought at a low price, find out the price, compare prices, in our office in Minsk, st. Installers 9. Low cost for Viadrus boilers only in our online store 100kotlov.by. Huge selection of solid fuel boilers in our warehouse. We also deliver to the cities of Baranovichi, Bobruisk, Brest, Vitebsk, Glubokoe, Gomel, Grodno, Zhlobin, Ivanovo, Kalinkovichi, Kobrin, Lida, Minsk, Miory, Mogilev, Nesvizh, Oshmyany, Pinsk, Polotsk, Postavy, Rogachev, Slonon , Slutsk, Smorgon and other cities of Belarus

Come to our office, we will be glad to every visitor!

100kotlov.by

Different modes of operation

In order for the solid fuel boiler to switch to night mode, I do the following:

- Clean the grate.

- They fill the fuel and wait for it to warm up.

- Turn the smoke flap and reduce the boiler output.

In the morning, they open the flap and the holes on the doors, after which they shove the grate through the open ash doors. After the end of the work, the doors are closed.

The ash chamber needs to be cleaned two to three times a week; thermal protective gloves are required for work.

Solid fuel boiler Viadrus U22 С / D

Viadrus U22 c / d boiler

Viadrus U22 С / D is a heating boiler capable of operating on different types of solid fuels, including coal, logs, fuel briquettes, pellet pellets. The difference between modifications C and D is only that the model with the D index is characterized by a wider door of the loading chamber, and this makes it possible to load thicker firewood into the boiler when kindling.

The basis of the design is a sectional cast iron heat exchanger. In addition to the front and rear sections, solid fuel boilers of different sizes have several internal sections. Accordingly, the more sections there are, the more powerful the model. The range includes nine standard sizes for the C series and seven for the D series.

The heat exchanger sections connected to each other form a single volume filled with liquid. The inner space is reserved for the kindling and ash chamber. The rear section has a chimney outlet, in the upper part there is a supply circuit branch pipe, in the lower part - a return circuit. The front section has doors for the loading chamber and ash pan. The size of the heating unit affects the structure of the internal sections.

For more convenient regulation of the chimney damper opening, the handle is installed on the front panel. There are also two air supply channels to the boiler. The first is a flap on the ash chamber door. The force of its opening, as well as the volume of air that is supplied to the combustion chamber from under the grate, is adjusted either by an automatic draft regulator, or manually by means of a screw. On the door of the loading chamber, there is also an opening for air supply directly to the combustion chamber of the heating unit. The force of its opening is regulated by the owner.

To monitor the temperature and pressure of the fluid in the system, there is a thermomanometer on the top cover of a Czech solid fuel boiler. Its sensor is immersed in the rear section, and the device itself is brought into the control box.

The body of the Viadrus solid fuel boiler has a special type of thermal insulation, which reduces heat losses and, thus, increases the performance of heating equipment. The casing is coated over the insulation with wear-resistant and heat-resistant paint.

Review the table to understand the main specifications of the Viadrus U22 C.

| Viadrus U22 C Specifications | |||||||||

| Number of sections | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Power (coal), kW | 11,7 | 17,7 | 23,3 | 29,1 | 34,9 | 40,7 | 46,5 | 52,3 | 58,1 |

| Heated area, m2 | 120 | 180 | 230 | 290 | 350 | 410 | 460 | 520 | 580 |

| Fuel consumption, kg / h | 1,9 | 2,9 | 3,8 | 4,7 | 5,7 | 6,6 | 7,5 | 8,5 | 9,4 |

| Efficiency% | 75-80 | ||||||||

| Chimney diameter, mm | 156 | 176 | |||||||

| Cost, rub. | 49 200 | 52 000 | 55 900 | 60 150 | 64 550 | 71 800 | 76 250 | 81 200 | 89 850 |

As well as the parameters of the Viadrus U22 D boiler.

| Viadrus U22 C Specifications | |||||||

| Number of sections | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| Heated area, m2 | 220 | 270 | 330 | 380 | 440 | 490 | 530 |

| Fuel consumption, kg / h | 6,4 | 8,0 | 9,6 | 11,2 | 12,8 | 14,4 | 15,7 |

| Efficiency% | 75 | ||||||

Overview of Viadrus solid fuel boilers

The use of solid fuel boiler equipment, in addition to solving the issue of gas supply, also has an economic justification, since the price of these types of fuel is significantly lower than the cost of household natural gas.

To study this issue in more detail, in this article, as an example, the main types of solid fuel boilers from the Czech manufacturer, the Viadrus company, which has been producing boiler equipment since 1920, will be presented.

Solid fuel for domestic heating boilers.

Direct burning wood-fired boilers

The main distinguishing feature that all Viadrus solid fuel boilers possess, regardless of the type of operating unit and the type of fuel used, is the possibility of a section-wise increase in the design capacity.

The working area of the boiler is assembled from several cast-iron sections, which are connected to each other using bolted connections with special nipple nuts. Installation of additional sections allows to increase the size of the combustion chambers, ash pan and water heat exchanger, thereby increasing the overall capacity of the unit.

The main technical characteristics of direct combustion wood-fired boilers, depending on the number of sections used, are indicated in the table shown in the figure below.

Technical characteristics of wood-fired boilers.

Among the main aspects that you should pay attention to when buying, the following consumer qualities can be noted:

- Solid fuel boilers of direct combustion are the simplest version of boiler equipment from this manufacturer, due to which a relatively low cost, a high level of reliability is achieved, as well as the ability to install and connect with your own hands, without the involvement of qualified specialists.

- The use of such units is allowed in closed water heating systems with an installed pump.providing forced circulation of the coolant.

- For long-lasting and safe operation, all models are equipped with a water overheating protection system as well as a grate water cooling system.

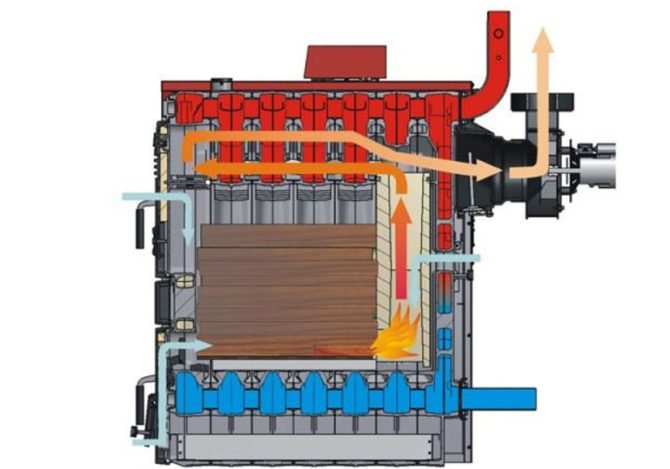

The photo shows the principle of operation of a direct combustion wood boiler.

Note! For normal operation of boiler units of this type, the relative humidity of the wood should be no more than 20%, and the maximum diameter of the log should not exceed 100 mm.

Pyrolysis boilers with afterburner

The pyrolysis, or in other words, gas-generating solid fuel boiler Viadrus also assumes a sectional increase in power, however, it differs from direct combustion models in that it uses a two-chamber principle of fuel combustion.

- In the first, loading chamber, which has a relatively large volume, gradual drying and degassing of wood is performed, and in its lower part, i.e. in the recovery zone, there is a slow combustion of fuel with a limited amount of air at a temperature of + 560 ° C, which leads to the release of volatile substances and combustible wood gases.

- In the second afterburner, the process of mixing volatile substances and combustible gases with secondary atmospheric air takes place, as a result of which they burn out at high temperatures, which can reach +1200 ° C.

The pyrolysis principle of burning wood, coal, or other types of solid fuels allows you to reach higher temperatures, and, accordingly, receive more heat energy from each conventional unit of fuel used. This, in turn, significantly increases the efficiency of the boilers, and also leads to significant savings in fuel materials.

The principle of operation of a pyrolysis-type boiler unit.

The Viadrus pyrolysis solid fuel boiler, depending on the number of working sections, can be equipped with an electronic or thermostat control system.

- The electronic system is installed on boilers with 3 to 5 working sections... Such a system allows for more flexible adjustment of operating modes, but its operation requires a permanent connection to the electrical network.

- Thermostat control system is installed on more powerful equipmentwhich can consist of 6-8 working sections. It is completely non-volatile, and allows you to automatically regulate the supply of fresh air and the removal of exhaust gases, as well as control the temperature of the boiler working area and the temperature of the coolant in the heating system.

.

Technical characteristics of Viadrus pyrolysis boilers.

Note! For normal operation of pyrolysis boilers, the relative humidity of the fuel should not exceed 20%, and the temperature of the return water in the system should not be lower than +60 ° С.

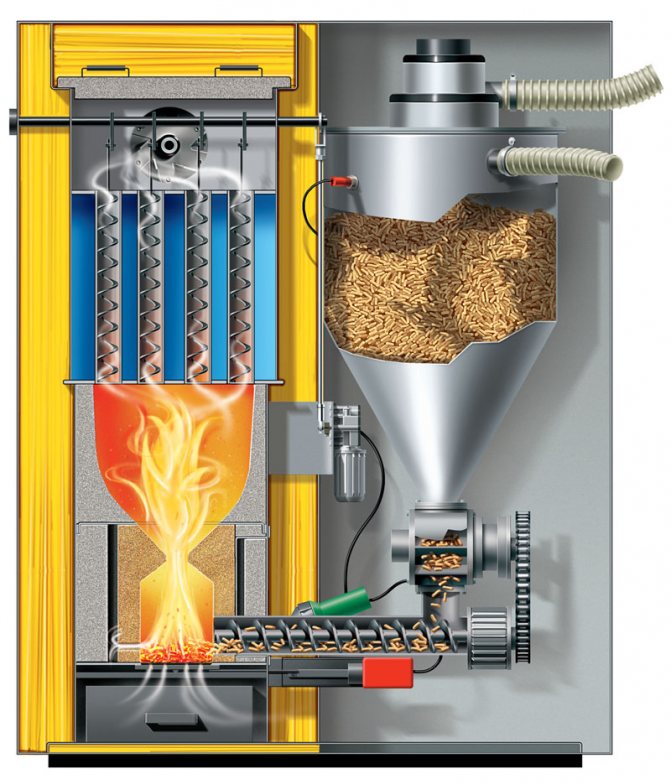

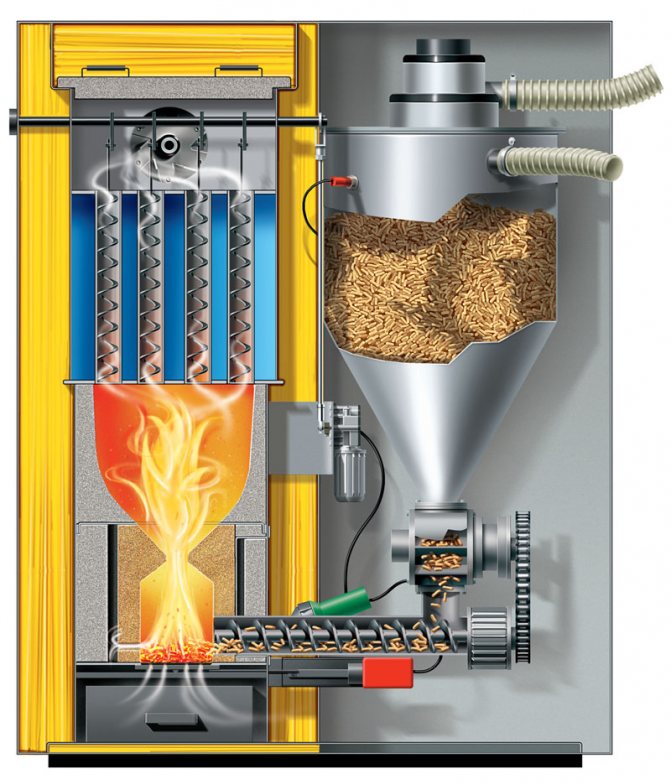

Pellet heating boilers

A relatively new and most economical development is the Viadrus solid fuel boiler, which runs on pellets. They are compressed granules made from dried and crushed wood waste or haulm and cake of agricultural crops.

The increase in the operating power of the pellet boilers is also carried out by installing additional sections, and the adjustment of the operating parameters can be carried out in automatic or manual mode.

- During operation, a certain stock of pellets is stored in the fuel bunkerfrom which, by means of a screw fuel supply device, they automatically enter the burner.

- In the burner, when the primary air enters and the temperature is high, the pellets glow intenselyreleasing volatiles and flammable gases.

- The evolved gas and saturated hydrocarbons enter the combustion chamber, where in the secondary atmospheric air they are completely burned with the release of a large amount of heat.

- Exhaust gases passing through the heat exchanger give up a significant amount of their heat to the hot water heating circuit, and at the outlet have a temperature of no more than +160 ° C.

All pellet boilers are equipped with an electronic control system that allows you to fully automate its operation. In addition, they are equipped with a protection system against overheating of the coolant, which automatically turns off the burner when the temperature reaches + 96 ° C, as well as an anti-freeze system, which automatically turns on the burner when the coolant cools down to a temperature of + 5 ° C.

The scheme of the operation of a pellet heating boiler.

Advice! The factory operating instructions for this type of boilers recommend the use of fuel pellets with a diameter of 6 to 10 mm, with a relative humidity of up to 12%, and a specific ash content of up to 1.5%.

Owner reviews

To fully understand what the unit of this brand is, you need to read the reviews on the Viadrus solid fuel boiler. For example, the Viadrus U22 D boiler. Users confirm that with careful treatment and correct operation, the device works stably and in accordance with the specified technical characteristics.The temperature is kept according to the specified error of 2-3 ° C. A single bookmark of firewood is enough for 1.5-2 hours. After a good warming up of the boiler and the entire system, the user closes the damper and the fuel smolders. Thus, the logs burn twice as long, but immediately after kindling, the owners do not recommend using this mode: only on a high-quality heated system. People note the high reliability of Viadrus U22 D, the doors open and close easily, and the system works as it should.

Feedback from the owner of the Viadrus boiler The furnace at the Viadrus boiler turned out to be small and completely inconvenient. Firewood 20-25 cm is included there. If you heat with coal, then it also enters in small volumes. Well, and accordingly, the whole thing quickly burns out and you need to often put it on. In winter, our temperature reaches - 40 or more, and we have to constantly be near the boiler. So no pluses can fully compensate for this. Yang

Some owners of Czech boilers of the U22 4D model note the effective operation of the draft regulator in the device, but at the same time complain about the problems with soot accumulation due to the use of raw logs, and sometimes the formation of soot in the chimney.

As a rule, the reviews on the Viadrus solid fuel boiler are positive. If there are drawbacks, then they are behind incorrect operation or initially the wrong choice of the device according to the technical characteristics. In the event of any breakdown and a valid warranty, the user can apply for a free repair to the company's specialists. Therefore, Viadrus boilers can be safely called reliable.

Installation procedure

Installing the boiler drum

1 Place the boiler drum on the plinth

Second On the upper part (flange) of the rear section of the boiler, install a seal φ 8 × 60 × 3 and attach the heating water flange. Weld the flange to the heating water system in advance.

3 On the lower part (flange) of the rear section of the boiler, install a seal φ 86 × 60 × 3 and attach a return water flange with a branch pipe for inlet and outlet valves. Weld the flange to the return water system in advance.

4 After connecting the boiler to the heating system, screw the elbow with the inlet and outlet cock to the outlet of the return water flange.

5 Place the chimney on the chimney and insert it into the chimney opening.

6 Screw the draft regulator to the hole in the upper part of the front section.

7 Two threaded holes Js 4.6 "in the front section are closed with plugs Js 6.4".

Installation of shells

1 Remove the casings from the carton

Second According to the picture, install the connecting material on the sides of the shell and attach the consoles

3 Unscrew the lower anchor bolts, install the side shell consoles. Push the front consoles between the washers with nuts and the front section housing, push the rear consoles directly onto the anchor bolts. While lifting, insert the bearing edges of the shells behind the upper anchor bolts. Tighten the nuts of the lower anchor bolts.

4 Remove the insulation from the top of the shell. Install a thermomanometer in the control box and screw the box to the upper part of the shell. Before installing the upper part of the shell on the boiler, reinsert the insulation, insert the thermometer sensor into the thermometer socket, and screw the pressure gauge sensor into the pressure gauge socket.

5 For the heads of the screws for the iron, install the rear part of the shell with insulation.

6 According to fig. 8 mount the smoke flap control.

7 Screw the brush into the attachment.

Filling the heating system with water:

Water for filling the boiler and heating system must be clean and colorless, free of suspensions, oil and chemically aggressive substances. The parameters of the circulating and additional water must meet: ČSN 07 7401, if the water hardness does not meet the required parameters, the water must be treated.Even repeated heating of water with high hardness does not prevent the deposition of salts on the walls of the boiler body. The deposition of 1 mm of limestone reduces the heat transfer from metal to water in this place by 10%.

Heating systems with an open expansion vessel mean direct contact of heating water with the atmosphere. During the heating season, the expanding water in the vessel absorbs oxygen, which increases the effect of corrosion and, at the same time, the water evaporates. For replenishment, only water with parameters according to ČSN 07 7,401th can be used. The heating system must be thoroughly flushed in order to get rid of impurities. During the heating season, it is necessary to maintain a constant volume of heating water in the heating system and ensure that the heating system is deaerated. Water from the boiler and heating system must not be discharged or taken for various purposes, except for the necessary repairs by Tai etc. When the heating Water is discharged, the addition of a new one increases the risk of corrosion and deposit formation. If it's necessary add water to the heating system, always add to the cooled boiler to prevent cracking of the sections.

After filling the boiler and heating system with water, it is necessary to check the tightness of all connections.

The completion of the installation and the performance of the heating test must be recorded in the Warranty Certificate.