Among heating systems, a flueless boiler using natural or liquefied gas occupies a special place. Having appeared on the market relatively recently, these devices have become a real breakthrough in the application of new technologies in heating systems. Consumers also appreciated it - recognizing the convenience of use and reliability of these boilers. However, when choosing a device for an individual heating system, you should carefully study all the qualities in order to be sure of the right choice.

What are smokeless boilers

In the design of heating boilers, a large place is occupied by the problem of removing combustion products. In gas boilers, in comparison with other types of heat-generating devices, there are much fewer such products than in solid fuel ones, but despite this, their design is a very responsible matter.

The classical scheme for installing a gas boiler, like a solid fuel unit, requires that a chimney be provided in the building structure itself. And this is a rather complex structure erected during the construction of the entire structure of the house. A smokeless gas boiler is another matter; its installation does not require a high chimney and smoke ducts in the walls of buildings. And the place of installation of this device is not so rigidly tied to the structure of the building and the communications laid in its premises.

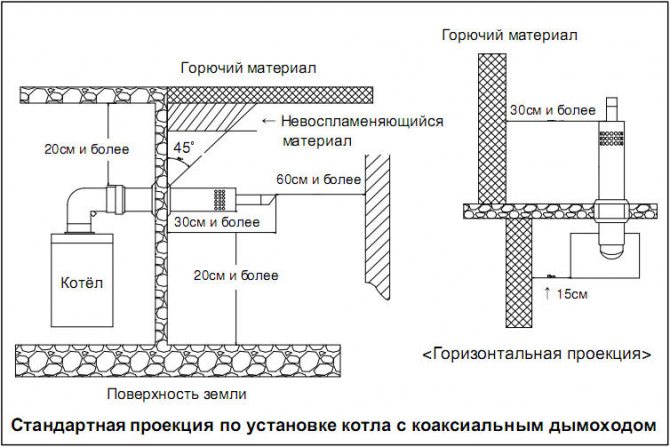

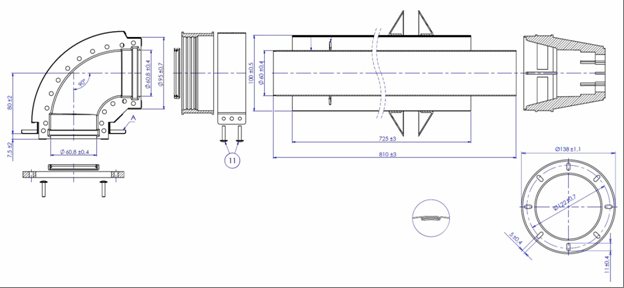

In the technology of smokeless heating boilers, a scheme is implemented in which air is supplied for fuel combustion and combustion products are removed through a coaxial channel. This is the fundamental difference between conventional chimney boilers with an open gas burner and a closed combustion chamber. As for the design of the coaxial channel, it is nothing more than two pipes inserted into one another, in which a thin inner one is designed to remove combustion products, and the second, of a larger diameter, is intended for the flow of atmospheric air.

Such a coaxial chimney can be installed in any outer wall of the building, which allows for the most convenient location of heating equipment inside the building.

Chimneyless boilers - their pros and cons of operation.

The advantage of underfloor heaters equipped with a coaxial pipe is installation in a living room. To fit the boilers into the interior, the decoration of the walls and the joints of the chimney with the wall is selected.

More details about coaxial chimneys and their use for gas boilers can be found in the video below.

Coaxial boiler in the interior of the apartment

Apart from this, other pluses:

- simplicity and low cost of installation;

- there is no need to install supply and exhaust ventilation;

- high power of units of such a design that they heat large areas;

- some gas models are equipped with convection holes, which makes it possible to heat a room without a radiator;

- long service life.

The disadvantages of coaxial boilers are the smoke extraction system. The length of the smoke exhaust pipe is no more than 5 meters. During frosts, chimney boilers operate at high power, which is why more condensate forms in the coaxial pipe, which freezes and blocks the air supply and smoke extraction. The chimney blows out if it is not equipped with a windscreen.

The principle of operation of chimney boilers

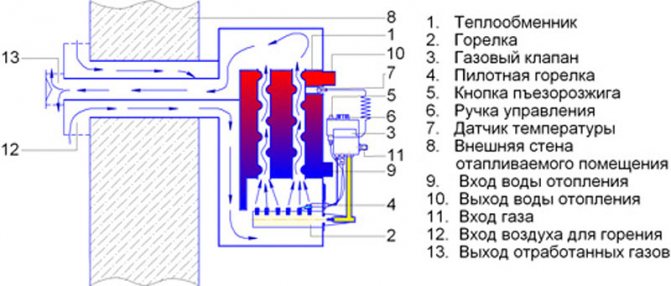

In principle, this group of heating devices is no different from conventional boilers with an open burner. In the heat exchanger above the gas burner, the heating medium for the heating system and water for hot water supply are heated.The movement of the coolant through the system is carried out under pressure created by a circulation pump. Burner ignition is controlled by a control system that reacts to data changes with a temperature and water flow sensor. The difference lies in how atmospheric air is supplied to the combustion chamber and how the exhaust gases are discharged.

The gas burner is located in a closed circuit; when a signal is sent from the control board, an electric turbine starts to work before igniting the piezoelectric element. Its design has two independent chambers with impellers located. One impeller wheel draws air into the combustion chamber circuit from the channel between the pipes of the coaxial chimney. The second impeller creates flow through an internal duct that draws air to the outside. 2-4 seconds after the start of the turbine, gas is supplied to the burner and the flame is ignited.

During operation, combustion products are removed through an internal pipeline. At the same time, given that the temperature of the exhaust gases is high, the air supplied to the combustion chamber heats up, which has a positive effect on the operation of the boiler.

The design of the coaxial channel is as follows, outside the building, the pipe extends 30-50 cm, depending on the design of the chimney. The outer contour is located at a distance of 15-25 cm from the plane of the wall, and the pipe through which the gases are discharged is extended beyond the outer contour by 10-15 cm. So during operation, both flows do not mix.

Floor standing boilers with a coaxial chimney: types, features

Due to the high efficiency of energy resources and efficiency of work, floor-standing boilers with a coaxial chimney are increasingly used for heating large-sized premises. What are the features of the device of this kind of thermal equipment, what types are produced, we will consider further.

Floor standing boiler

Features of the

For the operation of boilers - generators of this type, natural or liquefied methane is used, as well as propane - butane. As a result of gas combustion, a large amount of heat is released, it is transferred to the coolant, which serves as a source of heating water for household and other needs.

Important!

The coaxial chimney, which the generators are equipped with, has a two-circuit air exhaust system (pipe in pipe): combustion products and harmful volatile substances are removed through an inner pipe of a smaller diameter, fresh air enters the system through an outer pipe of a larger diameter to ensure the combustion process.

Benefits

:

- a high level of efficiency is ensured by the presence of a built-in cleaning system and a condensate trap in the chimney, which leads to complete combustion of fuel and its economical consumption (from 0.8 to 6 l / h, depending on the generated power)

- simple and easy to use

- fireproof, thanks to built-in fuses, when the ignition is turned off, the gas supply to the combustion chamber is cut off, which eliminates the risk of unauthorized fire.

Internal structure of the boiler

Views

They are manufactured in several power variations (from 10 to 60 kW), due to which they can be installed as the main source of heat in large private or warehouse premises, industrial complexes. The material for the heat exchanger is steel, which is less durable, or cast iron, with excellent heat storage and burnout resistance.

From the type of fuel efficiency:

- convection ones have a more affordable cost, its distinctive feature is the maximum generation of infrared energy, which is released as a result of gas combustion, and the absence of condensation

- condensing ones are large and have an improved fuel economy system, in addition to infrared heat, they use the heat that is released from the condensate formed in the device, this happens with the help of an economizer installed on the side walls of the generator (corrugated or straight pipes made of cast iron, in which condensate accumulates abundantly) ...

Important!

Depending on the manufacturer, floor-standing boilers with a coaxial chimney can be additionally equipped with an electronic flame simulation system, have a self-diagnostic function, frost protection, be equipped with separate boilers for heating water, which significantly affects the increase in the functionality of the device and ease of use.

What requirements should be considered for the installation of smokeless boilers

As with other gas equipment, flue-free boilers must comply with stringent government regulations regarding safe installation and operation. True, it is worth noting that the installation of such equipment is much safer than conventional chimney models with an open combustion chamber. Otherwise, the requirements for these devices are standard - they cannot be installed above the plates, the set distance must be maintained, the room must have a working alarm.

Devices are selected in terms of power, depending on the area of the heated room and the requirements for the volume and temperature of heated water. As for the coaxial chimney, it can be installed horizontally or vertically. When installed horizontally, it is done at a slope of 2-3 degrees towards the wall, so that the condensate formed between the circuits does not enter the combustion chamber.

A vertical chimney is installed when it is not possible to install a horizontal chimney, for example, when the distance between adjacent buildings is less than 1.5 meters or the chimney is located near a window. Under such circumstances, the horizontal gas discharge scheme is unsafe and the vertical chimney scheme is used.

The height of the vertical coaxial chimney must be such that the total length of the chimney does not exceed 5 meters. Another condition for installing a vertical chimney is that there should be no more than 2 bends in the structure.

Theoretically, a coaxial chimney can be made independently, there is nothing complicated about it. But on the other hand, professionals advise using branded components for the boiler and chimney. The fact is that manufacturers are developing universal chimney systems for different brands of boilers, but of their own production. At the same time, for other brands, these components may not be suitable both in size and in the method of fastening.

In branded accessories for the internal pipeline, stainless steel is used, and for the external one, either high-quality plastic or stainless steel.

Installation of a gas boiler with a coaxial output

The device of a heating system with a coaxial gas boiler does not have a complex circuit. Installation of all units is performed within 2-3 hours.

The general requirements for the device are:

- Chimney connection - the pipe is mounted in accordance with the current SNiP and the manufacturer's recommendations. To ensure good draft performance, it is forbidden to use more than two turning angles along the entire length of the flue system. The total length of the vertical chimney must not exceed 3 m.

- Minimum installation height - the distance is calculated along the outer wall of the building The requirements regulate that the head is located at least 1-1.5 m above the ground surface.

- Condensate drainage system - during operation, the boiler uses targeted condensation formation. Spent condensate will need to be removed from a special container into the sewer.

- The optimal conditions for installing a coaxial boiler are to install the equipment on the wall through which the chimney will be discharged from the building. To ensure the best draft characteristics, the chimney length should be within 1-1.5 m.

- You can avoid icing by installing an insulated, as well as a condensate trap.

Coaxial flue boiler models

To facilitate the choice, all the presented models of heating equipment are divided into three categories according to the following criteria:

- Installation type - the consumer is offered floor-standing coaxial gas heating boilers and their wall-mounted counterparts. Stationary models have great productivity, but are inconvenient in installation and subsequent operation. Wall mounted coaxial gas heating boilers are more popular due to their compact size and the presence of a large number of various functions.

- The number of heat exchangers - a coaxial double-circuit gas boiler, works to heat the hot water supply and the heating system. Modern models have a built-in buffer tank that provides almost instant hot water supply to the consumer. Coaxial single-circuit gas boiler, designed exclusively for heating, but has a greater power compared to a two-circuit analogue. If desired, after a small modification, an indirect heating boiler is connected to a heat generator with one heat exchanger.

- Manufacturer - popular models are offered by the following companies:

A chimney-free gas boiler is a profitable solution not only for houses and summer cottages, but also for classic apartments located on any one as well. Such double-circuit gas boilers without a chimney allow you to efficiently heat the house and at the same time not spend a lot of money, as well as use such a device, without notifying gas and other utilities, preparing documents, obtaining permits.

A chimneyless gas boiler is a functional heating unit, which, in addition to its classic heating function, is able to connect to various systems of the house and thereby ensure even greater efficiency and productivity, open up new opportunities for people.

What features do you need to be prepared for when the boiler is operating

What you need to pay attention to

First of all, turbo boilers are dependent on electricity. In the event of a power outage, it automatically turns off. On the one hand, this is fraught with cooling of the premises and the lack of hot water supply. But on the other hand, this means that the gas valve shuts off the gas supply, and the blocking system does not allow the burner to ignite. So in places where the power supply is unstable and where there are frequent power outages, you will have to consider the issue of emergency power supply.

The second feature is the need for regular maintenance by service center specialists. This is especially true for regions where natural gas has a large amount of impurities. Cleaning in the device requires not only the burner with a combustion chamber, but also the turbine.

The third point is that quite often chimney-free gas boilers that are too short, or vice versa, long chimneys can be blown out by gusts of wind. In most cases, this problem is solved by installing a deflector instead of a decorative grill.

Malfunctions of a smokeless gas boiler

As for characteristic faults, gas boilers without a chimney have the same typical faults as conventional chimney ones:

- Control board malfunctions - most often the cause of the malfunction is a factory defect, voltage drops or water leakage from the heat exchanger (for many wall-mounted models, the control board is located in the lower part, under the main equipment);

- Malfunctions of electrical equipment - sensors for temperature, pressure, water flow, centrifugal pump and turbine usually fail after a long period of operation;

- Heat exchanger leakage is especially common in double-circuit gas boilers without a chimney after 7-10 years of operation. In the places where copper plates or pipes are soldered, holes are usually formed through which water or coolant seeps;

- A coaxial chimney often simply needs to be cleaned of dust and carbon deposits. But if this is not done regularly, during boiler maintenance, the likelihood of debris getting into the combustion chamber and clogging the burner nozzles increases significantly.

But, despite this, smokeless gas heating boilers are currently one of the most reliable and safe heating devices. In a closed combustion chamber, when the turbine is stopped during blowing by the wind, the gas supply is instantly cut off. The burner will reignite only when the automatics diagnose all equipment and allow gas to start again.

Types of boilers

Chimneyless boilers can be wall-mounted and floor-standing. The most effective are wall-mounted, single-circuit, smokeless gas boilers. This model performs its main function not only due to the combustion of gas, but also due to the use of the residual heat of the condensate obtained from the vapors of the air discharged into the atmosphere. Particularly good results can be achieved with low-temperature operation, in particular, if a certain section of the heating system is made according to the underfloor heating principle. Since the temperature of the coolant in the "warm floors" system is only 45-50 ° C, this makes it possible for water vapor to condense more strongly in the exhaust gases.

Condensing units have the highest efficiency, environmental friendliness and minimum fuel consumption. The disadvantage of such equipment is the need for a special drainage of condensate obtained during operation. Such moisture should not be discharged into surface water or soil, as it is saturated with acids and can disturb the bacterial microflora. For wall-mounted condensing boilers, the chimney must only be made of high-quality plastic that is resistant to acid fumes.

How to choose the right chimney boiler for living quarters

First of all, when choosing, it is necessary to decide on the place of installation of a gas flueless boiler in the room itself. Among the models of many manufacturers, there are both parapet and wall models. To install the parapet model, it is necessary to take into account the location of the windows - the chimney should not be at the same level or below the level of the windows.

It is recommended to install a wall-mounted gas flue gas boiler on the outer wall of the room. As an exception, installation on internal walls is allowed, but the length of the coaxial chimney should not be more than 5 meters.

Boiler power is selected depending on the area of the heated room. As for a specific brand, here professionals advise you to pay attention to how much this brand is represented on the market, and whether this brand has a network of service centers. This is an important point, since the maintenance of this equipment requires not only trained specialists, but also the availability of branded spare parts. So, most domestic brands, like global brands of manufacturers of climatic equipment, advise to carry out diagnostics and maintenance of smokeless boilers at least once a year, before the start of the heating season.

A chimneyless gas boiler allows you to solve the problems of the device of individual heating in almost any houses and apartments, providing warmth and comfort in the most severe frosts.

Choosing a gas boiler without a chimney

A small room or the impossibility of installing a stationary chimney is not an obstacle to the installation of heating equipment. The solution can be chimneyless gas boilers.

They are equipped with their own smoke extraction system, which does not require a separate area, it is compact and is installed directly above the device.

What is such equipment

According to their purpose, chimneyless boilers practically do not differ from ordinary ones. They, like all other models, can be used for space heating and hot water preparation, but they have a slightly different combustion chamber. There are differences in the principle of work.

If for the normal functioning of a conventional gas apparatus, the presence of a chimney and a draft is necessary, then these models use a coaxial pipe for air intake and exhaust gases.

Equipment of this type is designed for heating rooms up to 300 m² and can be connected to the system from one or both sides. Combustion products are removed from them through a coaxial pipe, consisting of two elements. On the inside, gases are removed, and on the outside, air is supplied to the boiler.

They are very convenient not only constructively, but also because they are fireproof. Hot combustion products are isolated from the walls of the building by cold air coming from the street.

Also, the advantage is the boiler's undemandingness to the presence of draft and air flow, these operations are performed forcibly, using a fan built into the device.

What do we pay attention to?

Heating devices with a closed combustion chamber include a coaxial chimney for a gas boiler. It is designed to keep your device running smoothly.

And serious requirements are imposed on it, because combustion products are removed through it, which are very harmful to human health. Therefore, it is recommended to install it through a wall that does not have window and ventilation openings.

For all other parameters, the criteria for choosing a gas flueless boiler do not differ from others. When buying it, you should also pay attention to:

- power

- compactness

- design

- ignition options

The brand of the manufacturer is also an important factor, and since each of them has a wide range of products, it is worth evaluating several different samples in order to decide which one is best suited for the room.

Chimneyless boilers are divided into:

Let's start with floor standing boilers from the Slovak manufacturer Proterm. They are non-volatile and have an efficiency of 90%, are reliably protected from overheating and are supplied assembled. Floor standing boilers have high power ratings and can be used for heating large rooms, and also have other remarkable characteristics:

- reliability

- ease of use

- relatively low price

- the ability to change fuel

The next of the noteworthy models are gas boilers with a coaxial chimney from a Korean manufacturer, today they are the leaders in the sales market, and not only because they have a low cost, but also due to a fairly large list of high performance indicators.

When choosing these devices, even the brand is not so important. It can be:

All of them are well adapted to use in the Russian climate and have high quality indicators, a large number of safety sensors and are very easy to operate.

German smokeless boilers are undeniable in their reliability and quality. Not only are they designed for a long service life, but they also have a lot of advantages and among them environmental friendliness is not the least.

The brand plays a significant role when choosing, but other parameters should not be overlooked:

- dimensions

- power

- installation method

They are also important and must be considered when purchasing.

Manufacturers and brands

Equipment of this class is produced by all well-known European companies, as well as domestic enterprises. If we consider its cost in relation to wall and floor options, then it was distributed in the same way as for boilers with an open combustion chamber. Wall-mounted options are cheaper, while floor-standing ones have the highest price.

If we make a comparison between local and foreign models, then there is no particular difference between boilers with an open and a closed combustion chamber. Import samples also have the highest prices, and products from a domestic manufacturer are almost 50% cheaper.

If we consider the models of boilers from one manufacturer, for example, the very popular Italian company Baxi. Then her gas-free, floor-standing devices have a price in the range of 2000, and wall-mounted samples - about 1000 euros. The cost of wall-hung boilers with an open combustion chamber under the brand of this company is about 700-800 euros.

But, despite the higher price, chimneyless boilers are in great demand, especially when equipping apartment heating systems in multi-storey buildings.

For small spaces

Increasingly, residents of city apartments have to think about the problems of heating their premises. This option is currently the most profitable and has a number of advantages over a centralized system.

But an ordinary chimney boiler in a city apartment cannot be installed, and a closed-loop apparatus is a worthy replacement for it.

It is easy to install, does not require additional costs for chimney equipment, has a compact size and modern design, and also allows you to turn on heating during the off-season. These advantages and the presence of a coaxial pipe made the smokeless boiler very popular and in demand in the Russian climate.

Heat exchanger, power and combustion chamber

If you decide to buy a smokeless gas boiler, we recommend choosing the appropriate model, relying on such a parameter as the power, which should be suitable for a particular house or apartment, living area.

Determination of power is performed according to the following recommendations and instructions:

- If we talk about the standards and the general opinion of experts, then about 1-1.5 kW of power is spent on heating 10 square meters of living space. In this case, the ceiling should be standard and have a height of no more than 3 meters;

- The resulting power indicator must be increased by an average of 15-25 percent, since during the heating process, heat can be lost if it is very cold in the house, there is a big minus outside, windows and entrance doors are periodically opened and drafts are observed;

- You can find out more about the maximum and minimum power your boiler has in the accompanying instructions and technical specifications for the device;

- An important role is played by such an indicator as the performance of the heating unit, it is also indicated in the standard documentation. Also, it is important to consider how long and in what volumes you will be heated hot water, how many points of water intake you are going to connect and use.

A single-circuit smokeless boiler has one more significant difference from a double-circuit one. It can be equipped with a secondary or bithermal heat exchanger. The first is a curved tube that has turns combined with ribbed plates. As a supplement to such a system, an outlet and an inlet branch pipe are used; in this case, the water is heated by means of a secondary heat exchange element, which is located in the lower part under the firebox.

The primary and secondary circuits also differ in their temperatures. In the primary, the water warms up by no more than 80-90 degrees Celsius, the secondary has an even lower temperature, not exceeding 60-65 degrees. Thus, you will not be able to burn yourself on such a pipe even if accidentally touched, and if necessary, the pipe belonging to the primary circuit can be thickened or additionally protected.

If, during long-term operation, you need to clean a certain section of the pipe, you can simply drive out the water. If the contamination is more complex, it is not necessary to disassemble and dismantle the entire structure, it is enough just to unscrew the necessary unit and, after cleaning, connect it to its original place.

Bitermal designs have a more budgetary cost, in contrast to the primary ones. Primary ones, in turn, can be supplemented with an electromechanical valve. The bithermal heat exchange medium has the following features:

- It is presented as one, combined by a heat exchanger unit;

- Consists of four branch pipes, two of which are hot water supply and the second two are connected to the heating circuit;

- The pipes are characterized by a cellular structure, the circulation of water is carried out and controlled by a central channel;

- Small dimensions and similar weight, while the hearth is not equipped with a three-way valve and additional wiring;

- The price for the installation and the equipment itself with such a heat exchanger is lower than other models and variations;

- Water is able to heat up, but in one of the circuits it is stationary, on the basis of which a layer of scale forms on the inner walls of the pipe. The channels are complemented by a small and narrow lumen.

Even if the circuit is closed, the water in it continues to regularly heat up to the highest possible temperatures. Therefore, in the event that you decide to open the tap, do not put your hands under the water right away, as boiling water may pour out of the tap.

The disadvantage of a double-circuit system, in comparison with single-circuit boilers, is the complexity of such units, they are supplemented by various pipes and wiring. As a result, there are often leaky areas that can cause water leaks.

The combustion chamber may differ in its type, variety. Based on this, they can be:

- Open type. Air enters the hearth directly from the room. All exhaust gases are introduced through the chimney. The advantages of the variety include efficiency, since the products are not supplemented with fans, due to this, the noise level is significantly reduced. In order to install such boiler equipment, it is necessary to use the services of a professional, since the draft in this case, as well as the ventilation, must be in good working order. Based on this, boilers with an open combustion chamber are more expensive;

- Closed type. Such variations are more effective, in this case the air is taken directly from the street, through the presence of forced ventilation. You can connect such a hearth to a coaxial chimney, due to which, installation can be done not only in the house, but also in the apartment. The disadvantages include the fact that in the cold season, the chimney can become icy, since a large amount of condensate forms inside it, which must be removed in a timely manner.

In this video clip, an overview of the Lemax Patriot gas parapet floor-standing chimney boiler is presented:

10/27/2017 1178 Pechnik (Moscow)

Floor standing chimneyless gas boilers are a great option and alternative if you have a limited budget or do not have a lot of free space in the room chosen for installing the boiler. Floor-standing gas boilers are chimneyless, despite their name, they still have a chimney.In terms of its external structure, it differs from the classic vertical one. Such a system is otherwise called coaxial, and it is brought out directly through the wall of the house, which is very convenient both in installation and operation.

Overview of rulers and manufacturers

- Some of the best heating devices are produced by the Slovak PROTERM brand. Such installations do not require additional connection to the electrical network, and their efficiency reaches about 85-90 percent. The advantages include a low price. The structure does not require assembly and is sold fully completed;

- Favorable ratio of affordable price, high quality and the simultaneous use of innovative technologies can be found in a number of such Korean, "Olympia", "Rinnai". The structures are equipped with special sensors that allow monitoring the heating temperature of the installation and, in the event of a malfunction, give a signal and automatically turn off.

Advice: if you want to buy an inexpensive and at the same time functional and reliable heating unit, we recommend that you first of all pay attention to domestic models. They are in no way inferior to foreign models, but they have an average cost of 30-50 percent lower. However, it should be noted that, compared to wall-mounted, floor-standing variations have the highest cost. This is due to their greater productivity, efficiency and high power. For example, the cost of wall-mounted models from Italian ranges from 1,500 to 2,000 euros, while similar hearths with an open combustion chamber are significantly cheaper (600-850), and a wall-mounted variation can be purchased in the price range from 900 to 1100 euros.

Interesting to know: install

floor standing flue gas boilersit is possible not only in a private and country house, but also in a standard apartment located in a multi-storey building. This will allow you to get an additional economical source of heating, as well as always have hot water and the ability to heat the apartment, even during the period when the central heating is turned off.

If it is impossible to install a classic vertical chimney for heating, smokeless gas boilers are used. For such heating equipment, a ventilated separate room for natural draft is not equipped.

Despite the name "chimneyless", such boilers have a chimney. Its role is played by a compact coaxial pipe, which provides traction and removal of smoke masses from the combustion chamber.

External outlet for coaxial flue gas vent

Positive traits

Among the main advantages, it is especially important to highlight the following:

- The installation and installation price is relatively low compared to other modern systems;

- Neutral design allows for indoor installation with any design and decor;

- For such structures, supply and exhaust ventilation ducts are not installed;

- The devices are distinguished by high power, which significantly increases their efficiency and efficiency, thereby allowing to heat premises with a large area;

- If the model has special convection holes, the heating function is possible even without radiators;

- Long service life.

Floor variations are the most powerful and massive

Gas boiler installed in a specially equipped room

Simple design and uniformity of the body allow the product to be in harmony with any interior

Heating systems of this type with a coaxial chimney, not located in the basement

Miniature floor model suitable for heating a small house or apartment

Important: the biggest drawback of such an installation lies in the chimney.Due to its small length (no more than five meters) and high power, a large amount of condensate begins to form on its inner surface in winter. As a result, the chimney can freeze, blocking the opening through which fresh air enters, and exhaust gases are removed. For reinsurance, it is worth equipping the pipe with a windproof element.

It is interesting to know: despite its impressive characteristics and parameters, even the most powerful boiler equipment of this type can heat no more than 250 squares in total, and a maximum of 300. With the correct installation and implementation of the exhaust system, you do not have to worry that the draft at certain weather conditions will not work at full capacity (this criterion is fully controlled by the fan built into the structure).

Floor standing chimney boiler

If it is necessary to heat large rooms, it is important to take into account not only the price of fuel, but also the indicators of its consumption. Today, the list of the most economical types of boiler equipment includes a floor-standing boiler operating on gaseous fuel, the equipment of which includes a coaxial chimney. Floor-standing type of boiler equipment is used for heating or supplying hot water in industrial premises and large residential buildings.

The floor-standing boiler runs on gaseous fuel, natural gas, liquefied methane or propane-butane mixture are used as such fuel. A floor-standing gas boiler is distinguished by the fact that there is an element in its combustion chamber that ensures the ignition of the incoming gaseous fuel. Also, the floor-standing appliance of any modification is equipped with a special fuse that cuts off the gas fuel supply after the ignition is turned off.

The so-called gas boilers without a chimney are actually equipped with a chimney system. This system, called coaxial, is dual-circuit. The combustion products are discharged from the unit through the inner pipe, fresh air enters through the outer pipe of a larger diameter.

One of the advantages of a smokeless smoke exhaust system is that the efficiency of the boiler plant is 10 - 12% higher than that of an analogue with a conventional chimney.

A floor-standing gas appliance, in the equipment of which there is a coaxial chimney, is becoming very popular.

Chimney double-circuit boiler

For this type of device, an appropriate smoke exhaust system is used - a coaxial type. It is a pipe-in-pipe chimney: a pipe of a smaller diameter inside a pipe with a larger diameter. In order to avoid contact of pipes during their internal connection, special jumpers are used.

How the coaxial chimney is located depends on different nuances. If the exit of the chimney from the building to the street through the wall is difficult or even impossible, the coaxial smoke exhaust system is positioned vertically. In other cases, especially when the forced type of ventilation of a double-circuit boiler system is used, the coaxial type chimney is installed horizontally.

At the same time, a very important nuance related to fire safety is taken into account: the opening of the smoke exhaust system should be located one and a half meters above the boiler.

The heating system, which has a coaxial chimney, has an important advantage: the air for fuel combustion is taken not from the heated room, but from the street. The fact is that the inner pipe of the smoke exhaust system is used to remove the combustion products, and the outer pipe is used to supply fresh air to the boiler furnace.

Of course, one cannot do without a smoke exhaust system for boiler heating. A double-circuit non-chimney gas boiler is a device in which there is no need to install a stationary chimney.Most often, a stationary-type chimney cannot be installed due to the fact that the room is very small.

Double-circuit boiler systems of a non-chimney type are used, like their counterparts, which have a stationary chimney, for heating premises and heating water for household needs. Chimney boilers have special smoke removal equipment - the so-called coaxial chimney.

Fig. four

It should be noted that the pipe of the coaxial smoke exhaust system must be led outside the building through the wall, on which there are no window and ventilation openings.

There are two ways to install chimney boilers: wall-mounted and floor-standing.

When purchasing a chimneyless boiler, you need to pay attention to a number of nuances:

- Power;

- Compactness;

- Design;

- Ignition type.

Another important nuance that must be taken into account is the brand of the manufacturer. Each of the companies has a wide range of boiler equipment, and you need to evaluate samples of different brands in order to choose the most suitable device.

The design and principle of operation of smokeless boiler equipment.

Chimneyless, like classic gas boilers, operate in heating mode - single-circuit, and also as water heaters (DHW) - double-circuit.

A distinctive feature of the design is a closed combustion chamber. The burner, through which the gas heats the water in the system, is located in a sealed chamber. Thus, carbon monoxide, soot and smoke from fuel combustion do not penetrate into the room, and the efficiency of the boiler increases.

Oxygenated combustion air enters the closed chamber through the external chimney block. The air heated by the burner element heats the copper circuit through which the coolant flows. Then the "exhaust" air, together with the fuel combustion products, goes out through the inner block of the coaxial pipe.

Scheme of operation of a floor-standing coaxial boiler

The coaxial flue gas vent is simple to design. These are two coaxial pipes of different diameters, fastened together. Thus, the heated gas waste is cooled by the air entering the chamber, making the boiler fireproof and environmentally friendly for the residents of the house. Cooling the combustion products, the air enters the combustion chamber already heated, which saves energy.

To prevent insufficient draft, gas boilers of high power are equipped with deflectors, which increase the air flow by one and a half times. If there is a likelihood of wind blowing, a special wind protection unit is installed at the pipe outlet.

Gas boiler without chimney

Natural draft boiler equipment should be installed in a special room, a boiler room - because it requires oxygen from the air contained in the room. However, the use of forced draft will make it possible to install a boiler of one type or another running on gaseous fuel in any room.

To do this, it is necessary to use a special smoke exhaust system - a coaxial chimney. Before installing a chimney of this type, it is necessary to carry out a number of calculations, taking into account:

- The power that the boiler develops;

- Type of fuel burned;

- The thickness of the walls of the room;

- Outside air temperature;

- The number of boilers connected to the coaxial flue gas system.

System design: a pipe of a smaller diameter inside a pipe of a larger diameter. It is important to note that the width of the gap between the walls of the inner and outer pipes must be the same in all parts of the chimney, even in its elbows and bends. There are two important parts in a coaxial flue gas system: a flue cleaning device and a condensate collector.

A coaxial chimney is a smoke exhaust system that is used not only for a gas boiler, but also for boiler plants operating on liquid and solid fuels.