Floor insulation - this is a necessity that arises for residents of apartment buildings, especially those living on the ground floor, where the cold enters the apartment through the basement.

As a rule, floors in multi-storey buildings are made of reinforced concrete structures that have low thermal insulation properties, so they need insulation to achieve comfortable living conditions and save on heating an apartment.

How to insulate the bathroom floor?

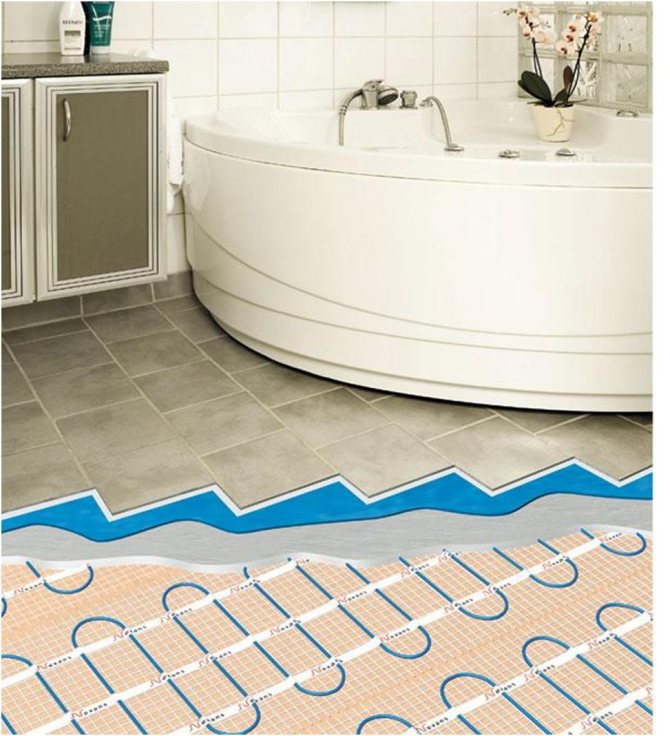

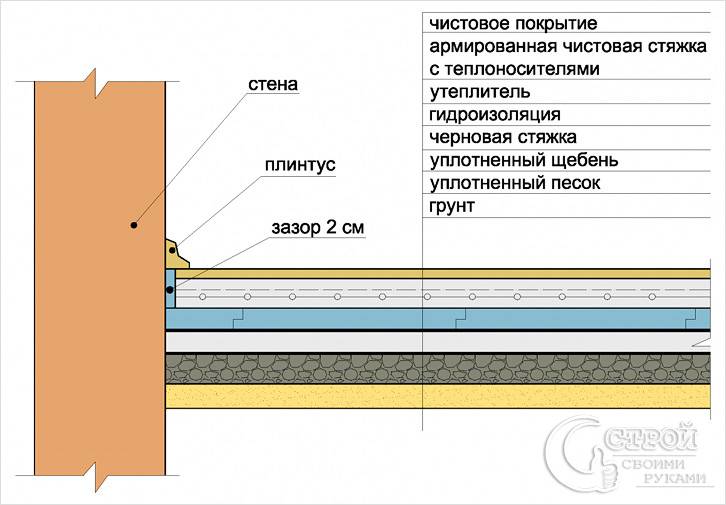

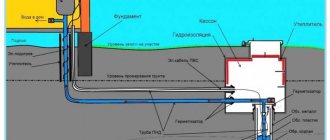

When insulating a floor, the first step is to build a waterproofing layer that will protect the base of the floor from water and moisture. For this, a polyethylene film laid in two layers is perfect.

Next, you can proceed to the selection of thermal insulation material. Fortunately, the modern market offers the consumer a variety of roll materials that form an excellent thermal insulation coating, which also acts as an excellent sound insulator.

If your apartment is on the ground floor, then the first step is to take care of its insulation - all interpanel joints and other openings must be sealed with polyurethane foam. The floor, as a rule, is insulated with the help of the construction of a cobbled sheathing, between the bars of which a heat-insulating material is installed.

The most popular material for floor insulation is mineral wool, which, in addition to excellent thermal insulation properties, is an affordable, environmentally friendly and durable material.

The floor structure when applied is as follows: waterproofing, then a crate made of wood, between which cotton wool, chipboard or fiberboard sheets are installed to level the surface and the finishing floor covering (laminate, carpet, linoleum or another type).

The quality of work is determined by heat loss and heating costs. With thermal insulation, special attention must be paid to the quality of the materials used for repairs, since products of dubious quality only in very rare cases provide the proper level of thermal insulation.

Recently, the insulation of loggias and the creation of small living rooms from them has been gaining popularity. Also, many have attached a loggia to the room, removing the window block. Someone equips a workplace with a computer desk. And everyone is faced with the problem of how to insulate the floor.

The first advice, if it is possible to take the battery to the loggia, do it. In this case, you will significantly reduce the energy consumption of the warm floor.

Choice of flooring - tiles, laminate or carpet will also affect the performance of the system. For example, tiles have high thermal conductivity and therefore will give more heat to the air, and laminate and carpet will heat up faster, spend less electricity, but the air will warm up less.

Correct thermal insulation will also reduce floor heating time and save energy.... We recommend that you first insulate the walls of the loggia and only then the floor, since you need to reliably insulate the perimeter of the heated floor so that the heat does not go out into the street from it. Most often, the walls are insulated with 10 cm foam, which is covered with drywall. We recommend laying compacted (extruded) foam on the floor.

If you are planning a laminate, then lay plywood on this foam, for rigidity and fix it. Next, instead of the standard laminate backing, a 3mm reflective metallized backing is installed.

On it infrared thermal film and laminate.If tiles are planned, then a metal (masonry) mesh is laid on this foam, a heating cable is poured onto it and a screed 3-5 cm is poured. further tile. Or, first, a metal mesh, a screed, and then a thin cable, which is located in a layer of tile adhesive.

It is strongly not recommended to lay cable or mats on loggias without thermal insulation. The power of the cable for a cold room must be at least 200 W / m2, i.e. for 4 m2 cable power not less than 800W .

Installation of devices

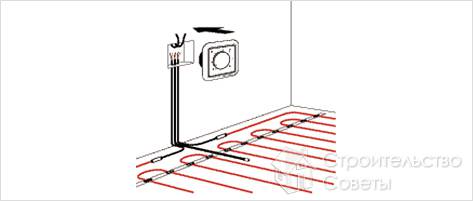

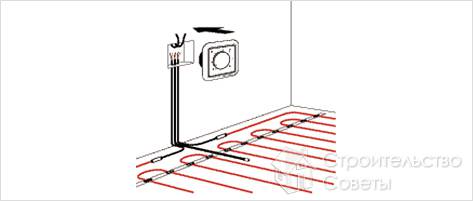

The thermostat is usually installed in the wall. The height of the placement from the floor is limited only by the lower threshold of 30 cm. When choosing a place for installing the device, you need to take into account the upcoming arrangement of furniture in the bathroom. The thermostat should not be covered by furniture, it should be accessible. The thermostat must be powered with a voltage of 220 V.

For the installation of the temperature sensor in the wall and in the floor, a special groove is made, designed for laying the cable in a corrugated pipe. A cable is laid from the sensor along the corrugated pipe, which comes into contact with the thermostat. We cover the corrugated pipe in the groove with a cement-sand mortar.

Thermal insulation of a wooden floor

When building a house, as a rule, all work on its insulation, including the floor, is carried out at the initial stage. However, what to do if a ready-made construction option is purchased, requiring work on its insulation?

Experts in this field say with confidence that this is not such a difficult job. Even a beginner can do it. One has only to thoroughly figure out which material to use to preserve heat and by what method.

The main rule when choosing a material is reliability and high level of thermal insulation properties... Most often, for this process, they choose: sheets of foam, mineral or stone wool, ecowool, cork insulation or foamed polyethylene.

Consider some of the nuances that arise when choosing such heaters:

- compare your financial capabilities with respect to the cost of the selected insulation (for greater awareness, it is important to know that each of the above examples has good thermal insulation, so advertising arguments will be superfluous);

- it is strongly recommended to use mineral or ecowool when small rodents are present in your house (mice are the most frequent tenants in the spaces between the foundation base and the wooden flooring);

- if you are looking for an economically viable option, then stop at expanded clay. Talk about its harmfulness and toxicity turned out to be untenable.

So, the required material has been selected. The stage of preparatory work begins. This includes dismantling the old skirting board and, directly, lifting the wooden floorboards themselves. It is very important, when removing the floorboards, be sure to leave its own serial number on each, this will allow you to simplify the reverse process for restoring the coating.

The next step for you is to inspect each log for the presence of rot, fungus or mold. If any of them have severe wear or damage, replace with a new one, and if this is not possible, treat with a protective solution. Next, you need to clean the base under the log - sweep or use a vacuum cleaner. The planned work is almost half done, now it is necessary to lay the insulation.

In the order of the first stage, a heat-insulating material is laid down, that is, sheets of stone or mineral wool, which is placed in the space between the logs. The principle of using expanded clay instead of cotton wool is the same, pour it at least 10 cm thick.

Its thermal insulation layer now you should definitely cover it with a layer of vapor barrier (for example, a polyethylene film).This material is laid with an overlap, while each of the strips overlaps the previous one by at least 15 cm. In fact, the process of floor insulation is completed. It remains to return each floorboard to its place, according to the numbering, and put the plinth.

Insulation of the floor in the bathroom

Inhabitants of panel dwellings still of the Soviet structure are annually waiting with bated breath for the arrival of winter. The point is not even that they like this time of year so much, here, rather, the point is the opposite. And there is a reason not to love winter for residents of similar houses.

If in summer, with extreme heat, cracks and holes in the walls serve as salvation from the hot air inside the living space, then with the arrival of frost, the same saving gaps turn out to be almost destructive for the well-being of the owners. Since not many people want to live continuously in a cool apartment (since the heating is completely different from what it was before), there is only one way out to insulate.

Virtually everything can be insulated. The most obvious solutions are insulation of windows (or replacing wooden ones with plastic ones) and insulation of the front door (or replacing them with a front door-safe). From unobvious insulation of walls and floors. Since the overhaul should be started specifically with floor insulation, it will be the main victim of the article provided.

So, floor insulation. To begin with, you should make your choice with materials. There are probably a number of modes of action to carry out the work provided. The following option is quite well-known among the representatives of the most adult generation: we open the floor, lay insulation, cover the floor.

The room in which work will be carried out is freed from furniture and other things that can interfere with work. Then the boards, which are the floor itself, are gently lifted. He works carefully so as not to destroy them, because these same planks will be introduced back. Then one or a number of layers of insulation are laid.

It is important to pay attention to the fact that the recognizable insulation "Styrofoam»In the given case will not become desirable. Its main problem is that the rodents that are found in old dwellings (and in the bulk of old houses they are), pull this product of the chemical branch into small balls. And as it turned out, polystyrene in their nests, warming not people, but a brood of rats or mice.

Therefore, it is better to focus on more innovative materials. After the insulation is laid, it is allowed to overlap the floor. It makes sense to strengthen the wood with each other with screws, since they are the most correct in use. Plus, fastening with screws (or self-tapping screws) will avoid floorboards squeaking for many years.

The last thing that remains is to lay linoleum (or other floor covering) on top of the already insulated floor and rejoice at the result of the creation of your own hands.

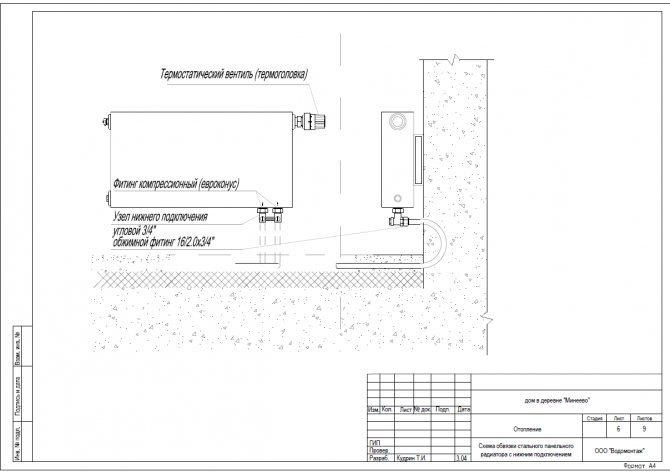

Preparing the floor for cable installation

Joint processing

At the stage of preparatory work preceding the installation of the "warm floor", it is necessary to perform the following operations:

- First, the floor surface is freed from ceramic tiles; Moreover, this operation is carried out using a perforator equipped with a nozzle of the "chisel" ("blade") type.

- After all the tiles are chipped off, the resulting space will need to be cleaned of dirt and dust.

- Immediately after this, the surface is treated with a special strengthening primer, which increases its adhesion to the screed layer applied over the heating system.

- Then the base of the floor is leveled with a cement screed, and after it dries, it is covered with a layer of waterproofing material. In order to reduce potential heat losses, a layer of insulation with a thickness of about 2 cm is laid on top of the waterproofing.

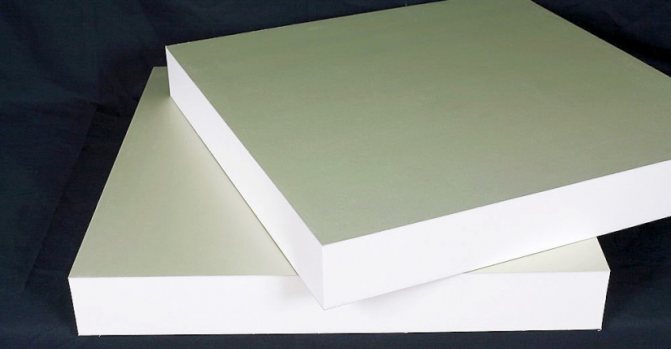

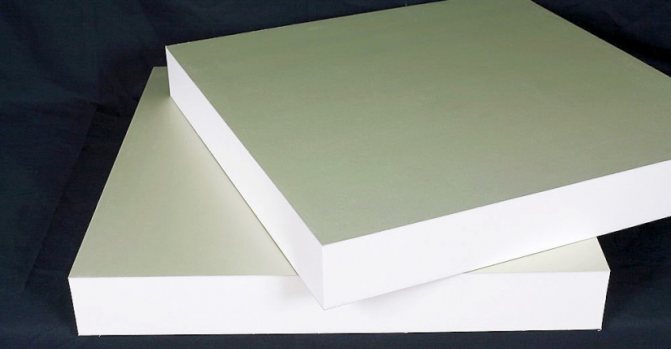

As a heater, it is allowed to use molded foam or foam boards.

The choice of material for insulation: basic characteristics, installation methods

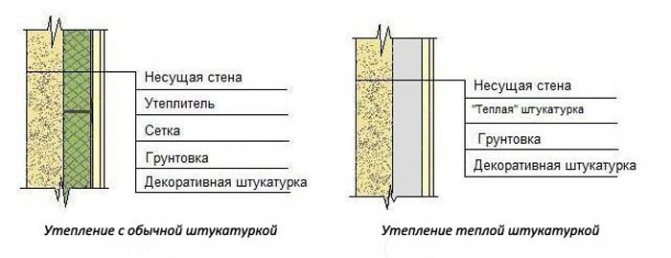

The choice of material for the thermal insulation device should be based on the main characteristics:

- minimum vapor permeability - keep the walls dry;

- thermal conductivity should also be the smallest;

- flammability class insulation and cladding - G 1;

- the material should not contain and highlight toxic substances;

- an important indicator in many cases becomes installation speed insulation and its cladding, technology availability to carry out insulation work independently.

Mineral wool: an inexpensive solution

The work flow chart is available, the materials are inexpensive, the execution is not difficult. Mineral wool should only be used in slabs.

Installation of a thermal insulation layer of mineral wool:

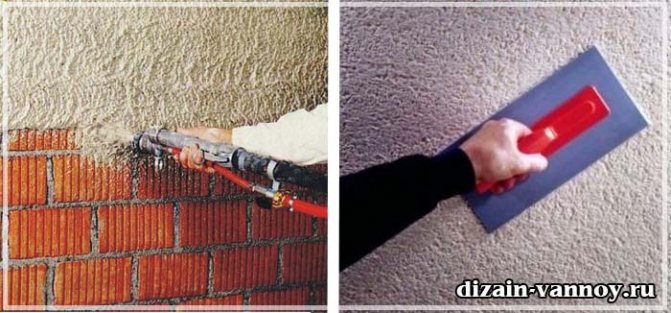

- the insulated wall is impregnated with an anti-fungal composition;

- a waterproofing film is fixed on the wall with a launch on the ceiling, floor, adjacent walls;

- a special wall profile is marked and attached;

- mineral wool insulation is tightly inserted into the marked sections, but without compression;

- the layer of mineral wool fixed on the wall is closed with a vapor barrier film;

- the last stage of work: facing with moisture-resistant gypsum board panels.

Foam glass: price and quality

Foam glass could be called the best material for wall insulation, if not for two points: its price is the highest in the group of heaters and the installation has difficulties with sealing joints with liquid rubber.

The material is versatile and has excellent characteristics:

- vapor permeability - 0.005;

- thermal conductivity - 0.05;

- environmentally friendly;

- it is highly durable and soundproof;

- there are no toxins;

- low water absorption;

- resistant to combustion, microorganisms, rodents.

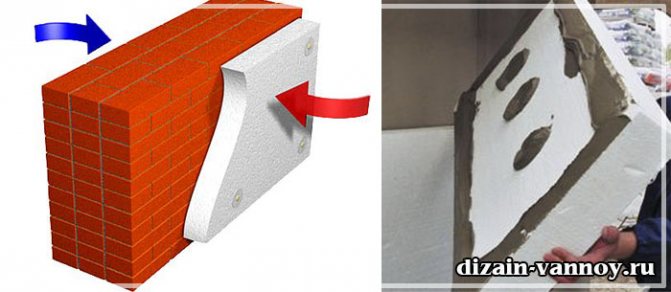

Polyurethane foam plates: pros and cons

Polyurethane foam plates have all the necessary characteristics for warming a bathroom:

- excellent water resistance and full vapor permeability;

- docking grooves are arranged at the ends to exclude cold bridges;

- a layer of foil is applied on the plates to return heat from infrared radiation to the room.

The disadvantage can be considered the thickness of the material: together with the cladding, the use of PPU boards will take about 10 cm of the floor, which is essential for small rooms.