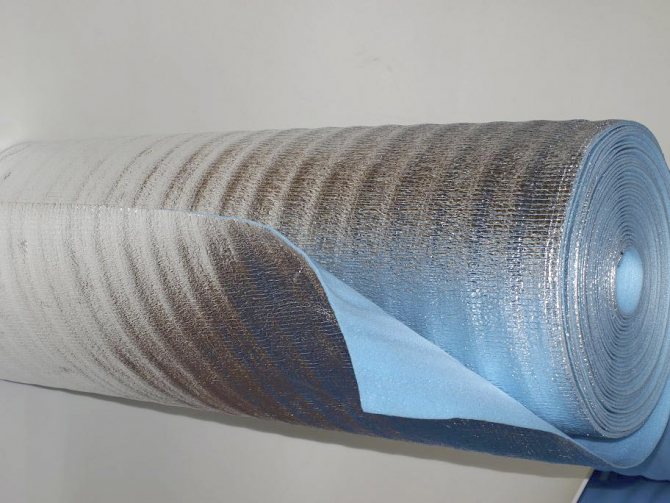

The cold season is accompanied by low temperatures and the desire to turn on the heating to the maximum. However, the cost of heating is quite high, but there is a way out. It consists in warming the premises with appropriate materials. Among others, foil polystyrene foam should be highlighted.

It has the ability to reflect heat and provides waterproofing, because the outer layer is a material that repels moisture. With the help of such a heater, you can isolate the room from external negative influences. Thermal insulation is quite simple to use. It is easy to install and highly efficient thanks to its honeycomb structure. The formed layer absorbs noise, which means that it allows you to achieve silence in rooms and reduce the amount of noise coming from outside.

Installation tips

The use of foil insulation allows you to heat-insulate the floor, walls and pipelines for various purposes. Great efficiency can be achieved with its help by insulating entrance doors and verandas. Before fixing the foil polystyrene foam, you must prepare some tools and materials:

- nails;

- a hammer;

- construction stapler;

- nail puller;

- foil insulation;

- construction tape.

The head of the nail can be quite large, which is even desirable. It is important to lay the material correctly with the reflective side facing inward. This will achieve a reflective effect when the heat radiation returns to the room. If you put the insulation on the other side, you will not be able to achieve the expected effect.

Material handling tips

Between the foil insulation and the finish, when installing the first, it is necessary to leave about 2 cm of free space. So, the room will be even warmer. The air will act as an additional insulator, and the structure will work like a thermos. It is advisable to enclose the material in a wooden crate when laying the material.

Sheets are never overlapped if you cut them from the roll or individual slabs. Installation must be carried out end-to-end, fixing the canvases with nails or a stapler. Foil polystyrene foam can have a self-adhesive layer, therefore, it is not necessary to additionally fix the insulation. But to ensure durability, it is better not to forget about nails.

If the material lacks an adhesive coating, rubber or acrylic glue can be used for attachment. Its application is carried out pointwise. As soon as all the sheets are laid in their places and fixed, the joints must be glued with foil tape. At this, we can consider that the installation is complete.

If you decide to use foil polystyrene foam for the walls, then you need to rid the base of mold. The surface is cleaned before gluing the thermal insulation, otherwise the fixation will be fragile. Among other things, the walls are treated with an antiseptic.

Manufacturers overview

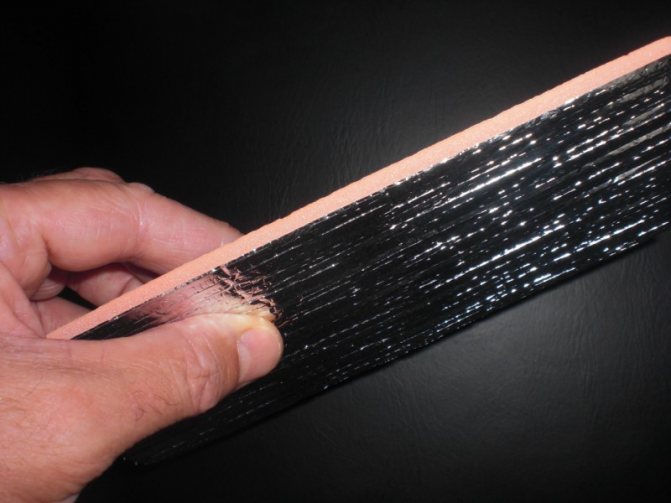

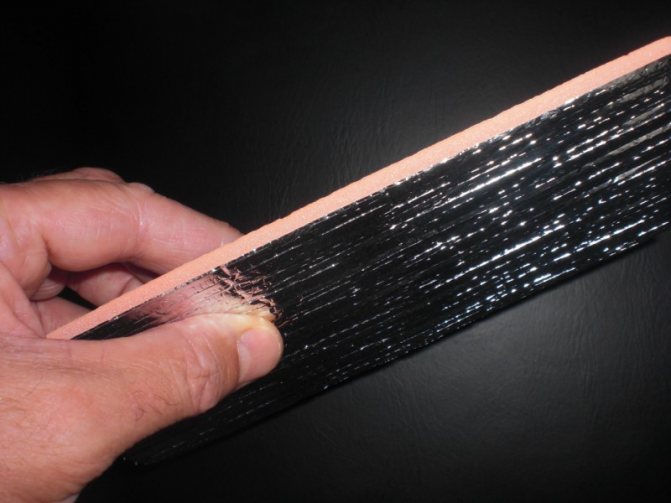

After examining the photo of foil polystyrene foam, you can understand how this material looks. But before you go to the store to buy insulation, you should familiarize yourself with the main manufacturers. Among others, the most popular in Russia should be highlighted:

- Folgoizol;

- Penofol;

- Germaflex;

- Isoflex;

- Ekofol;

- Izolon.

The price of the material will depend on the thickness of the polyethylene. For example, for a metallized roll "Jermaflex", the thickness of which is 2 mm, and the area is 50 m², you will pay about 1,680 rubles. This amounts to 33.6 rubles. per m².If the thickness of the mentioned material increases to 10 mm, and the area decreases to 25 mm², then you will have to pay 1692 rubles for insulation, which is equal to 67.7 rubles. per m². If you want to save money, you should pay attention to cheaper options for foamed polyethylene foil. You can buy them for 18 rubles. per square meter.

Thermal insulation of various structural elements

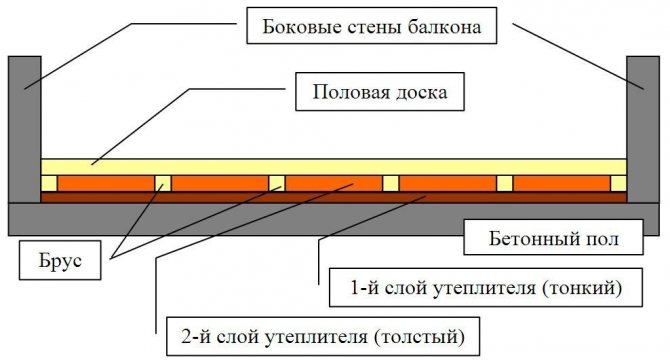

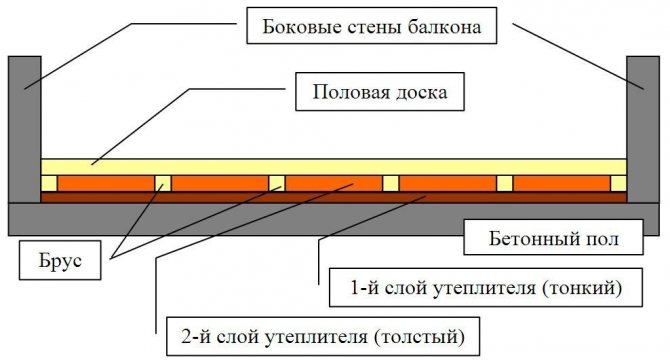

In frame housing construction, it is advisable to use reflective insulation for thermal insulation of the floor. It is better to mount "breathing" mineral wool on the walls without a foil layer, otherwise air exchange into the room will be difficult. The technology of fastening materials depends on the scope of its application: inside the house, insulation of the roof, floor or pipelines.

Wall insulation with Penofol or Penoflex

The difference between the materials is in the thermal insulation substrate. In Penofol it is foamed polyethylene foam, and in Penoflex it is extruded polystyrene foam. The technical characteristics and the method of their installation are similar.

Useful: Plasterboard walls: cladding a frame house

Sequence of work:

- According to the dimensions of the purchased insulation (roll width), fill a wooden frame on the walls. The slats are fixed with dowels, the maximum distance is 1 m.

- Cut Penofol - cut into pieces, the length of which corresponds to the height of the room with allowances of 8-10 cm on each side.

- Attach the roll material to the wall, straighten it and attach it to the wooden slats with a construction stapler. Penofol should not hang down or be overly stretched.

- Fill a crate of bars with a thickness of about 2 cm over the insulation. This will provide the required ventilated gap.

Such insulation is perfect for walls in the country., glazed balcony, utility room or animal housing.

Thermal insulation of the roof with three-layer insulation

Thin roll insulation is not enough for the roof. Penofol is best used in combination with mineral wool, an alternative is thermal insulation with foil mats made of basalt wool.

Briefing on the installation of insulation with two metallized layers:

- Lay waterproofing on top of the rafters in the horizontal direction. The canvases are fastened with an overlap in the direction from bottom to top.

- Press the hydro-barrier to the beams with counter-lattice strips. Next, they need to fill the horizontal bars of the main crate. From above, the installation of the roofing will be carried out.

- From the inside, attach strips with a thickness of 50-60 cm to the rafters, the installation step is 60 cm.

- "Shoot" a three-layer penofol to the formed frame, cover the seams with aluminum tape.

When attaching the inner lining, an air pocket must be provided. Ceilings are insulated according to a similar principle.

If Penofol is mounted in tandem with additional insulation, for example, mineral wool, then one metallized layer is enough.

Overview of "Penofol" type B

If you want to purchase foil polystyrene foam with double-sided foil, you should pay attention to the material from. It is produced in the form of rolls and is covered with aluminum foil on both sides. Insulation is used for internal insulation of rooms, loggias and roofs.

You can keep warm or cold indoors in winter or summer with an extra layer of foil. This material is blue in color and is based on closed cell polyethylene. The operating temperature varies widely from -60 ° C to + 100 ° C. The surface optical reflectance is 90% and the thermal reflectance is 97%.

Types and characteristics of reflective insulation

Foil insulation is a combined material consisting of a heat-insulating substrate and a reflective layer. The elements are tightly connected to each other by thermal welding. The reflective layer is a metallized lavsan film or aluminum foil.Substrate - various options for insulation that endow the material with certain qualities.

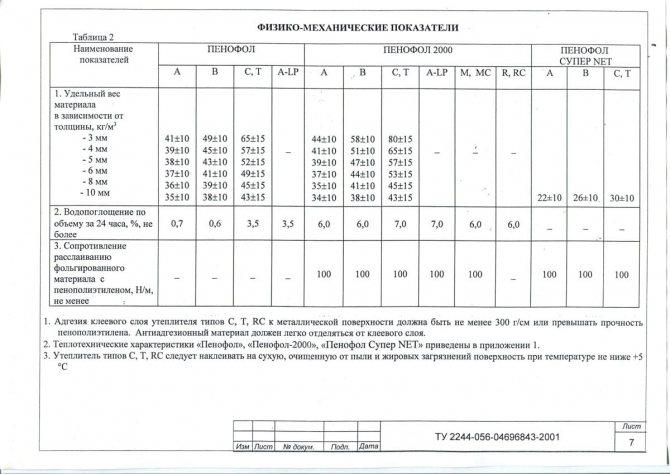

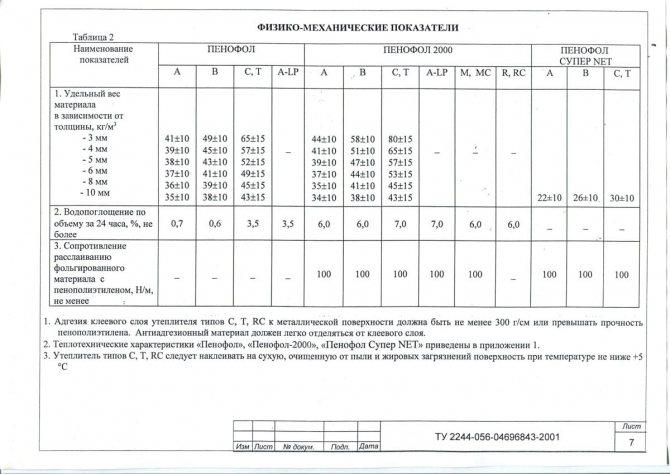

Penofol - foamed polyethylene foam

Roll insulation combining the thermal efficiency of polyethylene foam with the thermal reflectivity of aluminum. The unique product retains heat at three stages of propagation: convection, heat conduction and radiation. Penofol is made of different thicknesses, with one- or two-sided foil.

Characteristics of one-way reflective polyethylene foam:

- thermal conductivity - 0.037-0.049 W / m ° C;

- water absorption - 0.7%;

- vapor permeability - 0.001 mg / m * h * Pa;

- compressive strength - 0.035 MPa;

- heat capacity - 1.95 J / kg ° С;

- thickness - 3-10 mm.

Rolled reflective insulation is in demand when arranging a warm floor, warming steam baths, as a finishing substrate for linoleum or laminate. Penofol with a thickness of over 5 mm is used for thermal insulation of balconies, for sewer and ventilation pipes.

Mineral wool insulation

The thermal efficiency of mineral wool increases markedly after foiling. Two-layer insulation is endowed with an additional advantage - the protection of mineral wool insulation from water vapor and moisture. The final characteristics and scope of the material depend on the form of release of the reflective material.

Possible options:

- Roll insulation. The thermal conductivity coefficient is 0.04-0.041 W / m ° C, the thickness of the products is 20-100 mm. Rolls are supplied in lengths of 5-12 m. The density of the insulation depends on the technology of its manufacture. The Isover company offers a canvas with a density of 11 kg / m3, Knauf - 36 kg / m3.

- Sectional slabs. Thermal conductivity of mats - 0.036-0.039 W / m ° С, thickness - 50-100 m, density 32-40 kg / m3. Decent options: Rockwool Sauna Butts, a Paroc product.

- Cylinders and half-cylinders. Heaters for special purposes - thermal insulation of pipelines. "Warm sleeves" are made with one-sided outer foil.

Rolled and slab materials based on mineral wool are optimal for saunas - insulation of ceilings and walls. Due to its resistance to high temperatures, foil wool can be used to insulate boilers, boilers and other storage tanks.

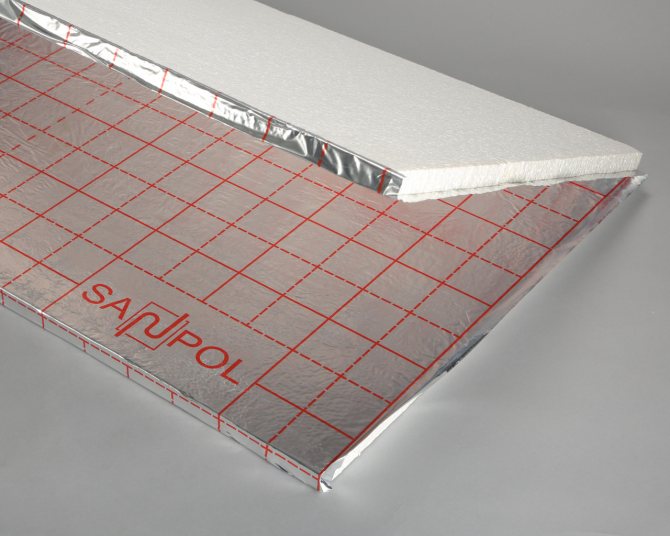

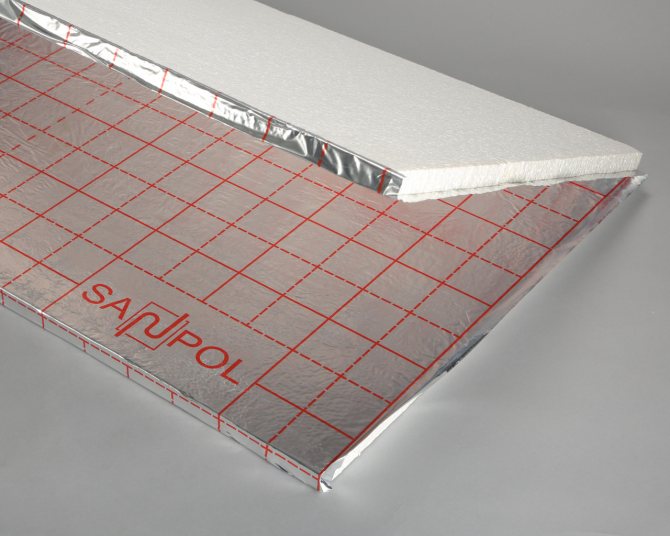

Expanded polystyrene with reflective coating

Durable thermoplastic made by fusing polystyrene granules. One side of the thermal insulator is covered with aluminum foil.

There are two possible forms of release of foil-clad polystyrene foam:

- single mats - slabs of different sizes with a metallized coating on one side;

- sectional rolls - expanded polystyrene inserts are placed on the foil film.

Reflective insulation perfectly resists mechanical stress and high humidity. The material does not grow moldy, does not rot, is not afraid of pests. Foil insulation retains its properties in the temperature range from + 180 ° C to -180 ° C.

Useful: Do-it-yourself metal frame for the house (LSTK)

Specifications:

- thermal conductivity - 0.035 W / m ° С;

- density - 40-45 kg / m3;

- vapor permeability coefficient - 0.05 mg / mchPa;

- thickness - up to 200 mm.

Most often, foil polystyrene foam is used for underfloor heating.. An aluminum reflector redirects heat fluxes upward to heat the finished floor covering. Achieved savings in heating costs - energy is not wasted on heating the sub-floor and floor slabs.

To facilitate installation, many manufacturers apply markings to the heat insulator - lines to fix the underfloor heating system.

Overview of extruded polystyrene foam from the manufacturer Ruspanel

This is extruded foil-clad polystyrene foam, which is produced in a wide range of thicknesses. The latter parameter can vary from 10 to 100 mm.Insulation is used for interior partitions, interfloor ceilings, exploited roofs, flooring, ceilings, baths, saunas, heating systems, refrigeration chambers and vans. It manifests itself perfectly in the formation of heat-reflecting layers of heating devices.

This foamed polystyrene foam for a bath provides a reflection of 97%, which allows you to protect the room and perfectly insulate it. The material is lightweight, which makes it easy to transport, ease the installation process and reduce shipping costs. With this material you can save on heating costs and get a constant reflection coefficient.

The insulation provides 100% waterproofing, does not absorb or let water through. The panels are environmentally friendly, they do not contain harmful substances, therefore they can be safely used for finishing premises for various purposes.

Overview of foil insulation from

Considering the characteristics of Izolon foil polystyrene foam, you can understand which insulation is better to give preference to. The described material has a low density ranging from 26 to 45 kg / m³. Perfectly reflects heat radiation at 97%. The material absorbs sound well up to 32 dB and above.

Vapor permeability can reach a limit of 0.04 mg / mhPa. The specific heat is 1.95 kJ. You may also be interested in the thickness of Izolon, it reaches 15 mm, while the minimum value is 1 mm. The operating temperature range ranges from -60 ° C to +105 ° C. Foil "Izolon" is often used for heat-insulated floors. This allows the building to be insulated and soundproofed.

Installation is carried out on the floor in one layer. You can use Izolon in conjunction with a dry screed or as a substrate under the floor covering. For such work, it is important to choose the thickness of the insulation. An additional advantage of using foil-clad Izolon is that it is not necessary to use steam and waterproofing together with it, since the material is not afraid of steam and moisture.

Technical characteristics of foil-clad penofol. Types of material. Roll dimensions and weight

The construction market is constantly replenished with heat-insulating materials. Manufacturers strive to continuously improve the technical characteristics of insulation intended for a wide range of consumers.

Against the background of similar materials, penofol is a bright and worthy representative of the industry and meets all the requirements for insulation and insulation of residential and non-residential premises, structures, pipelines, ventilation systems.

Material structure. What does it consist of

The name itself suggests that it consists of two parts:

- Base, in the form of expanded polyethylene, the pores of which are sealed and filled with air by 90%, it may differ in thickness and density;

- Aluminum foil, which is thermally attached to the base, has a high degree of heat reflection, to increase the effect it is polished, foil layer 20 microns thick.

Insulation is used as the main material for insulation, and as an addition to thermal insulation.

Scope of application of foil insulation

- For insulation of walls indoors and outdoors. These are residential, administrative, industrial buildings; children's institutions, hospitals, clinics, warehouses, shops, etc.

- When building premises with a high content of steam and heat (baths, saunas).

- For thermal insulation of pipelines, sewer and ventilation pipes.

- When insulating industrial refrigerators, machines transporting frozen food.

- When insulating cars, railway carriages.

- For greater heat transfer from heating batteries.

- When insulating floors and insulating roofs.

- When insulating balconies, loggias, verandas

Before using penofol, let's figure out the positive and negative aspects of the material. It should be noted that there are much more positive aspects.

Comparative table of Penofol with other heaters

| Material | Required thickness |

| Penofol type B, installed with two air spaces | 4 mm |

| Clay brick | 672 mm (2.5 bricks) |

| Silicate brick | 840 mm (3.5 bricks) |

| Expanded clay concrete | 490 mm |

| Aerated concrete | 384 mm |

| Mineral mats | 67 mm |

| Expanded polystyrene | 46 mm |

Pros and cons of insulating material

Benefits

- environmentally friendly material, since polyethylene and foil are used for packaging products;

- high ability to reflect heat;

- does not absorb moisture;

- does not let in noise;

- it does not burn and is capable of self-extinguishing;

- does not spoil by rodents;

- easy to use, no special tools are needed for its installation, it is enough to have scissors;

- convenient to carry, small thickness allows it to be rolled up and transported by any transport;

- thin compared to other materials;

- reflects the harmful effects of radiation.

disadvantages

The disadvantages of penofol include three points:

- soft material, bends when pressed, it cannot be applied with plaster or glued wallpaper;

- when working with penofol, a special glue is needed;

- outside it is used only as an additional material.

Varieties of types of penofol

There are several varieties of foil-clad penofol. Each of them is designed for a specific type of work.

- Type A - foil is applied to one side of the main surface, it is used as an additional material when insulating walls outside or inside a room, for insulating pipes.

- Type B - both sides of the base layer are covered with foil, it is used as the main insulating material for the insulation of partitions, ceilings between floors.

- Type C - one side is covered with foil, on the other - a self-adhesive compound, on top of it - a film that protects against sticking inside the roll, is used in places that are difficult to get to, and in poor conditions.

- ALP type - Penofol using a laminated layer, when polyethylene is glued on top of aluminum, is used in agriculture for insulating cowsheds, chicken coops, greenhouses.

- R type and M - embossed foiling on one side.

- Super NET type - to isolate networks.

- AIR type - for insulation of air ducts.

Penofol - 2000 is found on the construction market, which is distinguished by low technical characteristics, especially inferior in strength.

Specifications, dimensions and weight of a roll of insulation

- Large run-up of temperature parameters: from -60 ° to + 100 °.

- The reflective effect comes up to 97%.

- Thickness from 3 to 10 mm... There is penofol thick in 40 mmdesigned for work in the northern regions.

- Water absorption% - from 0.7 to 0.35.

- Compressive strength, MPa - 0.035.

- Water vapor permeability - 0.001 mg / mhPa.

- Thermal conductivity from 0.037 to 0.052 W / ms.

| Name | type A | type B | type C | AIR | 2000 type A | 2000 type B | 2000 type C | type AL-P | Super NET |

| Application temperature, ° C | from -60 to +100 | ||||||||

| Thermal reflection coefficient of the surface,%, not less | 97 | ||||||||

| Optical reflection coefficient of the surface,%, not less | 90 | – | |||||||

| Thermal conductivity coefficient, λ, at 20 ° C, no more than W / m ° C | |||||||||

| dry | 0,037-0,038 | 0,048-0,049 | 0,042 | ||||||

| - under operating conditions A | 0,037-0,038 | 0,049-0,050 | 0,043 | ||||||

| - under operating conditions B | 0,037-0,038 | 0,050 | 0,043 | ||||||

| Heat assimilation coefficient (with a period of 24 hours), s, W / m ° C | 0,45-0,51 | 0,44-0,48 | |||||||

| Vapor permeability coefficient, no more, mg / mh Pa | 0,001 | ||||||||

| * Resistance to heat transfer, R0 (depending on thickness), m2 ° C / W | 1,14-1,36 | – | 1,07-1,26 | 1,3-1,5 | |||||

| Dynamic modulus of elasticity, U, MPa | |||||||||

| under load 2 kPa | 0,26-0,39 | 0,26-0,40 | |||||||

| under load 5 kPa | 0,72-0,77 | ||||||||

| Relative compression, units | |||||||||

| under load 2 kPa | 0,03-0,9 | 0,04-0,10 | |||||||

| under load 5 kPa | 0,12-0,20 | 0,13-0,23 | |||||||

| Reduction index of the reduced level of impact noise, dB | 20 | ||||||||

| Specific heat, C0, kJ / kg ° C | 1,95 | 1,95-2,00 | |||||||

| Calculated mass ratio of moisture in the material, w, under operating conditions,%: | |||||||||

| BUT | 2 | ||||||||

| B | 10 | 2-5 | |||||||

| Flammability group | D1 |

Dimensions and weight

| Material type | Thickness (mm) | Width (mm) | Length, (m) | Area, (sq. M) |

| A, B | 3-5 | 1200 | 30 | 36 |

| A, B | 8, 10 | 1200 | 15 | 18 |

| ALP | 3 | 580 | 15 | 17,4 |

| Name | A type | Roll thickness, mm | Net weight of a roll, kg | Roll gross weight, kg | Roll diameter, m | Roll height, mm | Roll length, r.m | Roll area, m2 | Approximate roll volume, m3 |

| PENOFOL 2000 | BUT | 3 | 4,8 | 5,1 | 0,42 | 1200 | 30 | 36 | 0,212 |

| PENOFOL 2000 Economy | BUT | 3 | 8,0 | 8,3 | 0,49 | 1200 | 50 | 60 | 0,288 |

| PENOFOL 2000 | BUT | 4 | 5,8 | 6,1 | 0,48 | 1200 | 30 | 36 | 0,276 |

| PENOFOL 2000 | BUT | 5 | 6,8 | 7,1 | 0,53 | 1200 | 30 | 36 | 0,337 |

| PENOFOL 2000 | BUT | 8 | 4,9 | 5,2 | 0,48 | 1200 | 15 | 18 | 0,276 |

| PENOFOL 2000 | BUT | 10 | 5,9 | 6,2 | 0,53 | 1200 | 15 | 18 | 0,337 |

| PENOFOL 2000 | BUT | 13 | 7,5 | 7,8 | 0,60 | 1200 | 15 | 18 | 0,432 |

| PENOFOL 2000 | BUT | 15 | 8,5 | 8,8 | 0,65 | 1200 | 15 | 18 | 0,507 |

| PENOFOL 2000 | BUT | 20 | 7,3 | 7,6 | 0,61 | 1200 | 10 | 12 | 0,447 |

| PENOFOL 2000 | AT | 3 | 6,6 | 6,9 | 0,42 | 1200 | 30 | 36 | 0,212 |

| PENOFOL 2000 | AT | 4 | 7,6 | 7,9 | 0,48 | 1200 | 30 | 36 | 0,276 |

| PENOFOL 2000 | AT | 5 | 8,6 | 8,9 | 0,53 | 1200 | 30 | 36 | 0,337 |

| PENOFOL 2000 | AT | 8 | 5,8 | 6,1 | 0,48 | 1200 | 15 | 18 | 0,276 |

| PENOFOL 2000 | AT | 10 | 6,8 | 7,1 | 0,53 | 1200 | 15 | 18 | 0,337 |

| PENOFOL 2000 | AT | 13 | 8,4 | 8,7 | 0,60 | 1200 | 15 | 18 | 0,432 |

| PENOFOL 2000 | AT | 15 | 9,4 | 9,7 | 0,65 | 1200 | 15 | 18 | 0,507 |

| PENOFOL 2000 | AT | 20 | 7,9 | 8,2 | 0,61 | 1200 | 10 | 12 | 0,447 |

| PENOFOL 2000 | WITH | 3 | 3,8 | 4,0 | 0,42 | 600 | 30 | 18 | 0,106 |

| PENOFOL 2000 | WITH | 4 | 4,3 | 4,5 | 0,49 | 600 | 30 | 18 | 0,144 |

| PENOFOL 2000 | WITH | 5 | 4,8 | 5,0 | 0,53 | 600 | 30 | 18 | 0,169 |

| PENOFOL 2000 | WITH | 8 | 3,5 | 3,4 | 0,48 | 600 | 15 | 9 | 0,138 |

| PENOFOL 2000 | WITH | 10 | 3,6 | 3,9 | 0,53 | 600 | 15 | 9 | 0,169 |

| PENOFOL 2000 | WITH | 13 | 4,4 | 4,7 | 0,60 | 600 | 15 | 9 | 0,216 |

| PENOFOL 2000 | WITH | 15 | 4,9 | 5,3 | 0,65 | 600 | 15 | 9 | 0,254 |

| PENOFOL 2000 | WITH | 20 | 4,1 | 4,4 | 0,61 | 600 | 10 | 6 | 0,223 |

| PENOFOL | WITH | 3 | 4,2 | 4,5 | 0,42 | 600 | 30 | 18 | 0,106 |

| PENOFOL | WITH | 4 | 4,8 | 5,1 | 0,48 | 600 | 30 | 18 | 0,138 |

| PENOFOL | WITH | 5 | 5,5 | 5,8 | 0,53 | 600 | 30 | 18 | 0,169 |

| PENOFOL | WITH | 8 | 3,5 | 3,8 | 0,48 | 600 | 15 | 9 | 0,138 |

| PENOFOL | WITH | 10 | 4,0 | 4,3 | 0,53 | 600 | 15 | 9 | 0,169 |

| PENOFOL Super NET | BUT | 6 | 6,4 | 0,62 | 1200 | 15 | 18 | 0,461 | |

| PENOFOL Super NET | AT | 7 | 7,4 | 0,62 | 1200 | 15 | 18 | 0,461 | |

| PENOFOL Super NET | WITH | 7,8 | 8,2 | 0,62 | 1200 | 15 | 18 | 0,461 |

The nuances of installing foil-clad polyethylene foam

In the process of working with foil foamed foam, you need to take into account some features.

- There must be a distance between the material and the wall, floor, ceiling 1.5 - 2 cm for ventilation and moisture prevention. First, a frame is built of rails, penofol is attached to it, then, retreating 1.5 - 2 cm another frame on which drywall, plywood, etc. are installed.

- The foil side faces the heat source.

- Connect the parts of penofol using the butt method.

- Close the seams with foil tape.

- When working with penofol, you cannot use nails, self-tapping screws, screws - this leads to a violation of the thermal insulation of the material. Only a construction stapler is used.

- All wiring must be in good condition, because contact with the aluminum foil will lead to a short.

- When using material for floor insulation, you need to cover the cement screed with plastic wrap, and lay penofol on top.

Penofol is a trademark for foamed polyethylene foamed. In Russia it has an official permission for its production.

There are analogues of penofol on the market, but they are produced under different names: Ekofol, Isoflex, Izolon, Tepofol. When buying, you need to require documents for the material, confirming its quality, otherwise you can buy a fake, which, unfortunately, are present on the market.

With the help of foil-clad foam, it is possible to keep warm in the winter and, thus, to save on heating, and in the summer, to minimize the heating of the house.

Izolon installation tips

Foil "Izolon" is laid between the finish and the wall, while it is necessary to form an air gap. For this, wooden slats are stuffed onto which Izolon is attached with small nails. All joints should be glued with aluminum tape.

For such work, a material covered with foil on both sides is best suited. When insulating concrete floors, it is better to use a different material, placing it between the floor joists. After that, the insulation is laid on the base coat.

Quite often Izolon is used as a substrate for laminate flooring. If you decide to use the material when insulating a balcony, then it is better to resort to multi-layer installation. Izolon was the first to fit. Its installation is carried out in such a way that the reflection is external. After that, the foam should be laid, then the Izolon layer is applied again. At the next stage, a crate is installed on which finishing materials will be attached.

Characteristics of foil polystyrene foam

The heat insulator has the following distinctive qualities:

- Creates a seamless surface after installation.

- Ecologically pure.

- Easy to install.

- Resistant to moisture.

- Has a high resistance to cracking and compression.

- Provides additional sound insulation.

- Does not burn.

- Resistant to temperature changes.

Extruded polystyrene foam looks like foam and has many pores, but it is also durable. The plate itself has a smooth surface and can be of different colors. It was possible to obtain such a thermal insulator due to the combination of hydrogen and carbon atoms.During manufacture, the substance is foamed with the help of volatile agents. Steam can also be used. Due to this, the sheets do not absorb moisture, are durable and provide, after laying, not only additional thermal insulation of the base, but also its waterproofing.