The South Korean company Hydrosta is known as the largest manufacturer of plumbing fixtures and components for laying a heating and water supply network. The product lineup includes ball valves, bimetallic radiators, pipe-rolling materials and elements for their fastening.

But, the most popular are gas boilers from this manufacturer. The company began to produce these products in 2003, and at the moment almost all of the enterprise's capacity is directed to this industry.

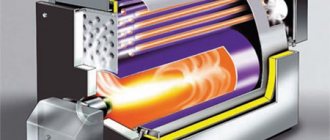

The Hydrosta gas unit is the perfect type of complete micro-boiler room. This type of equipment is intended not only for heating housing, but also for heating water.

If you hang two such boilers, then they will solve the problem of heating a house with an area of up to 400 sq. m. Equipping the unit with a closed-type combustion chamber allows it to be used in non-residential premises of a house up to five or more floors.

Design and control of these units

Of the design features of the Gidrost boilers, the following should be highlighted:

- Presence of a built-in microprocessor. It helps to track the tuning performance and smoothly change the power of the device. Also, the microprocessor controls the set temperatures of the heat carrier.

- Forced ventilation system. It effectively removes smoke gases.

- Remote Control. This is a portable mechanism: the digital indicator and sound signal present on it makes it possible to control from a sufficient distance.

- The functioning of the boiler nodal mechanisms is monitored by a telemetric system. If any breakdown occurs, a warning signal is immediately sent to the control panel.

- Modulated gas supply system. To increase the efficiency of these devices, they were equipped with electronic timers.

- Hydrosta boilers are small in size, modern design and easy to operate.

Major error codes

e0

Error e0 - malfunction of the room temperature sensor. Gas does not ignite properly. It is necessary to check that there is gas in the system and that the gas valve is not closed. Also, make sure there is gas in the cylinder or line.

e1

Error e1 - lack of water in the heating system. Insufficient amount of water in the system. Make sure that there is no breakdown in the cold water supply system, check the filters and, if necessary, clean or replace them.

e3

Error e3 - the water in the boiler has boiled due to overheating. The heating water circulates unevenly. It is required to check whether the filter is clogged and whether the stopcocks are open enough.

e4

Error e4 - the chimney is clogged. The combustion products are not discharged outside. It is required to check the pipes of the smoke exhaust system and, if necessary, clean the pipe or call a specialist.

e5

Error e5 - the burner flame is abnormal. Automation does not "see" the flame or it does not flare up enough. It is necessary to check the flame monitor and adjust the burner flame, or call a specialist.

e6

Error e6 - gas leak. Gas escapes from the system. Turn off the boiler immediately and try to identify and eliminate the cause of the leak yourself, or invite a technician.

e7

Error e7 - the connection between the thermostat and the control panel is broken. Poor contact or broken cables connecting the thermostat to the control panel. Check the cable connections between the controller and the thermostat and rectify the problem.

e8

Error e8 - the water temperature sensor is faulty. The sensor behind the control of the temperature of heating the water gives distorted information.Check the problem element and replace it if necessary.

her

Her mistake - the fan is faulty. The fan does not work or is dirty. Check the voltage supply to the fan and replace it if it fails. It should also be checked for contamination and cleaned if necessary.

ef

Error ef - the flow switch does not turn off the water for more than an hour and a half. The automatics noticed a lack of activity for a long time and filed a message. Check switch, clean and replace if necessary.

ea

Error ea - more than 5 times a minute, a signal is received to replenish water. The automation noticed that there was too much activity and reported a possible malfunction. It is necessary to check the serviceability of the supply circuit, filters and the presence of the necessary pressure in the water supply.

Water inlet filter

U0

Error U0 (uo) - boiler restart. The boiler tries to restart itself when a malfunction signal appears, which can be eliminated after a certain time or by the consumer independently.

Hinged boilers

Technical characteristics of mounted units:

- The heat carrier is completely protected from freezing.

- The wall-mounted version has a multi-level view of the security system.

- Hermetic design of the firebox.

- Hot water circuit. Equipped with two separate heat exchangers. They improve the performance of the device.

- Functioning principle. The heating of the outgoing gas is used to generate heat in greater quantities.

It's important to know: the excellent manufacturing settings of the wall unit allow it to be mounted in a very short time. There is no need to adjust the burner and do other difficult tasks.

Characteristics of floor-standing devices

Let's look at the example of Hydrosta HSB. They look like this:

These mechanisms are endowed with the same characteristics as the wall-mounted versions, but they are characterized by higher performance and additional functionality.:

- The heat exchanger is made of "stainless steel", which significantly increases the service life (up to twenty years).

- Reducing the noise level. The functioning of the mechanism was based on forced air injection, and the removal of waste after combustion. A special unit of the device - a muffler reduces the intensity of noise.

- The double-circuit mechanism Hydrosta HSB is installed in places with a large heating area. The equipment with a built-in storage tank significantly reduces the time for heating the liquid.

Diesel use

An excellent alternative to the options operating on gas is the floor-standing double-circuit diesel mechanism:

Speaking about these models, one should immediately note their shortcomings:

- Increased noise during the operation of the inflatable burner.

- The need to install a large container for fuel.

There are also some features of setting up this heating unit. They depend on the type and quality of the fuel oil.

The basic set of the device assumes the presence of an expansion tank, a circulation pump and safety options are also included here. You can control these mechanisms using a remote control and even a smartphone.

It's important to know: the double-circuit diesel boiler needs regular maintenance. It includes cleaning the furnace, cleaning the chimney system, cleaning condensate and more.

If you neglect this, then as a result, the performance of the device will noticeably decrease.

Gas boilers Hydrosta

___________________________________________________________________________________________

- Faults and repairs of Daewoo boilers

- Repair and operation of Rinnai boilers

Wall mounted boiler Hydrosta. After replacing the inlet valve, when the heating was turned on, the temperature began to rise very quickly to 90 degrees. Radiator connection parallel, two branches. In this mode, only the batteries closest to the boiler are heated, one on each branch. With DHW everything is fine. The pump is running. There is no air in the batteries.And how could the change of the make-up tap affect, and everything was shut off in the system, both direct and return. There may be several malfunction options, but in any of them there is a problem with the circulation of the coolant. Very simply, the coolant was drained from the unit, which means that instead of it it was filled with air, the air was driven into the system. Or alternatively, it lifted dirt from the system and clogged the filter. I need help with this problem. Underfloor heating and hot water supply have been operating from the Gidrost gas boiler for the third year already. For two years everything was fine. This spring, during the next visit of the gas equipment maintenance service, it suddenly became clear that something was wrong with us. They say that the expansion tank is not configured when the unit is started. And they did something with the expansion tank. Either pumped up, or relieved the pressure. I do not know. We are used to trusting such serious services. A few weeks later, summer began, the heating system was switched on according to the room temperature, therefore, naturally, in the summer the device worked only to heat water in the DHW system. In August, pressure suddenly began to drop. During the day, it could drop to critical 0.5 bar (the light on the display began to blink). Then one day in the village it turned out that there was a rush on the water supply line. They turned off the water supply, eliminated the leak in a day, gave water. On the contrary, pressure began to rise. I had to drain about 200 grams per day so that the pressure did not rise above 1.6 bar. A little later it got colder, and the boiler began to turn on to warm up the heating system of the TP. The pressure began to rise at a breakneck pace. Up to 4 liters of water have to be drained per day - the pressure rises from 1.6 to 2.2 bar. They invited the service department - nothing new. They did something with the expansion tank and left. And the pressure continues to rise. Since the departure of the service, 17 liters of water have been drained in less than 4 days. There are heavy leaks in the cauldron. The masters said - condensation. We suspect violations in the heat exchanger. And does it stop at these 2.2 or continue to grow? But 4 liters is something outrageous. If you are not exaggerating. Well, since you drain so much, then it's not about the expansion tank, although of course it could not be pumped up correctly. If so much merges, it means that so much is coming from somewhere. Can only be supplied from the DHW circuit. Pass from it to the heating circuit. There are two possible points where the extract air circuit and the DHW circuit can touch. This is a make-up tap. Leaks, does not overlap, seal damaged, twisted. And this is a secondary plate heat exchanger. Fistula inside this THAT. The pressure in the water supply system may have risen after repairs, so household (sanitary) water seeps into the heating circuit somewhere. Open the combustion chamber and inspect the heat exchanger. After 5 years of operation, the gas wall-mounted boiler Hydrosta began to malfunction, but I dealt with it myself. Now, after the next replacement of the fuse, the piezoelectric element has failed. How can I fix it? The standard service life of these models is 5 years, after which endless repairs become unprofitable, and it is better to replace the unit with a new one. Apparently, the power supply is out of order or the control board has burned out. Who can tell you about the Hydrosta hsg 100sd boiler? The heating is working properly, but a problem has begun with the hot water supply. When the tap is opened, the burner ignites, water flows, but the temperature is very low (25-30 degrees), set to 48. After 1-1.5 minutes, the burner goes out without reaching the temperature. In the right window of the remote control, the value 90 appears, but in heating, and the DHW is turned on again. And so it repeats itself. With a weak opening of the DHW tap, the temperature seems to rise. The heat exchanger has just been replaced. The numbers 90, as I understand it, are the temperature of the coolant inside the unit. You have overheated in the heating circuit of the secondary heat exchanger. Usually this is poor heat removal in the secondary heat exchanger, since it is clogged (overgrown with scale), it is washed or changed. There may be a blockage in the primary heat exchanger, then overheating will also occur during heating.Since you have changed the heat exchanger (it is not clear when and which one), call the masters again. The problem is that the pressure in the Khudrost boiler systematically drops to zero, and I cannot understand why. Will a cold water check valve help correct the pressure? You have two problems, most likely not related to each other. The pressure drop in the heating system is the result of a coolant leakage or discharge through the safety valve when the expansion tank is “deflated”. And turning on the device when the cold water tap on the mixer is turned off is the result of "inflation" of the DHW path. When the withdrawal of cold water is stopped, its pressure increases, and if it is possible to fit some more volume of cold water in the DHW path, it flows there, creating a short-term movement on the flow sensor. This is enough for the boiler to detect that hot water is being drawn off and try to start. The check valve will help with the second problem - the pressure in the hot water circuit will not decrease, when cold water is withdrawn, accordingly, there will be nowhere for it to flow when the pressure rises from the termination of the withdrawal. I noticed such a feature that when the Khudrost boiler is started in heating mode, the burner really turns on for 30 seconds, heats the water, and then a knock is heard (it can really boil). It starts to work after I drain the water from it, then fill in a new one. The air vent may have become unusable, although it is dumped when it is started after filling. If it is incorrectly filled with water, then air may remain in it, then it can knock, from the local boiling of water in the heat exchanger. And he can refuse to work. The air vent is designed for the gradual (in the process of passing by the coolant) removal of small volumes of air. Produces very few. It is not intended for complete air outlet when the unit is filled with coolant or immediately after filling. You can try (even if filling not according to the instructions) to disperse the air through the heating system, driving the pump without igniting the burner (stopping the ignition attempt from the remote control). Then it will slowly come out through the air vent in the unit and on the radiators. In my opinion, it is better to fill the system normally according to the instructions, including the apparatus, so that there are no large accumulations of air. Boiler hsg 200sd, in operation for 3 years. All summer in the disconnected state, a small leak appeared in the lower left corner along the filter housing. Having removed the lid, I found that it was leaking at the junction of the tube with the expansion tank and on the other tube behind. I use a mixture of water and glycol - good fluidity. The pressure is now 1.2 bar. In both problem areas, the spring clamps are loosened and rotate freely. Spacers with clamps, or something else? They are only in order not to fall away. Don't think about them. I purchased a hydrosta 350sd boiler, installed it, started filling it. During filling, water flowed from the case itself, removed the front cover and found that water was flowing out of this hole. Can you please tell me what it is and why is the water being discharged? The pressure sensor blinks at zero, that is, it turns out that there is no pressure in the system, or very small. A gas boiler HSG-130SD was installed, it worked for three years, but a problem arose. When hot water is drawn from the mixer, the pressure in the heating system drops to zero. What could be the problem? Most likely in an expansomate (expansion tank). When the Gidrost boiler is operating, something vibrates, it is not clear that something is rattling inside. I removed the lid, it works, everything is fine. Close it - it starts to rattle. How to fix it? And even during ignition, it sometimes happens that the burner starts up on the second attempt. Is this normal or not? If it started in a severe frost, then the pipe (inlet openings on the street) may have frozen over. The unit does not have enough air, and when the cover is removed, air is drawn freely from the room. Hydrosta HSG 160sd. When operating on room temperature, it cannot start normally.When the temperature drops, it starts to start, but after a few seconds the temperature on the remote control jumps by a degree and it has to stop. And the temperature immediately drops again by a degree. The boiler, accordingly, starts again. And this happens every time you start. It starts ten times before the temperature on the console stabilizes. Tell me how to solve the problem. What can you tweak? Either the ignition electrode is dirty, or the outside heat exchanger has not been cleaned for a long time, or the gas pressure setting has not been made, or there are problems with the chimney, both with the air supply channel and with the smoke exhaust channel. The wall-mounted gas boiler Gidrost has been operating on liquefied gas in cylinders for 2 years, during which time it has never been serviced. How often is it supposed to be serviced? How much does it cost and are parts included in the price? Regular prophylaxis refers to routine maintenance and is recommended as an annual procedure. The burner is cleaned, the automation is corrected, the cleanliness of the heat exchanger and the serviceability of the circulation pump are checked, the parameters of all sensors are measured. I have a Hydrosta hsg 200sd boiler, water is dripping from the drain. How to fix? And another question, how to check the expansion tank if you remove it? The water pressure in the system should be 1-1.2 bar. If the pressure exceeds the norm, you need to relieve the water pressure in the heating system to normal. If the pressure is normal, most likely, the water discharge valve is faulty (replacement is necessary). To check the expansion tank, you need to remove it from the system, unscrew the black plug, there is a nipple under the plug, you need to take a pump with a pressure gauge and put it on the nipple. The pressure should be 1-1.2 bar. If there is not enough pressure, you need to pump it up. If the expansion tank does not hold pressure, it must be replaced. Tell me, what errors can occur during the operation of the Khudrost boiler? If possible, codes and designations. Error E0 - Malfunction of the temperature sensor in the room controller. Error E1 - Not enough water in the system. Error E2, E4 - Malfunction of smoke exhaust. Error E3 - Overheating. Error E5 - Excess ignition voltage. Error E6 - Gas leak. Error E7 - Malfunction in the exchange of information. Error E8 - Malfunction of the temperature sensor in the heating system. Error E9 - Leakage of water from the heating system. Error EE - Fan malfunction. Error U1 - Button malfunction. Error Uo - Restarting the boiler. Error EF - Water flow switch has been turned on for more than 90 minutes. EA error - water replenishment signal is activated more than 5 times within one minute. EC error - Wrong unit model selected. Error Ed - Current frequency deviation. Error U8 - Malfunction of the hot water temperature sensor. I have a Gidrosta 100 boiler. When hot water is turned on, the boiler starts to whistle, it works normally when heating. What to do? An increase in power leads to an increase in the noise level. To reduce noise, several methods are used: increasing the number of fixing the boiler to the wall, using insulation for the chimney, adjustment may be necessary. Installed boiler hydrosta 350sd. The pump often turns on, a hiss is heard during ignition. The pump must run continuously. Possible cause of hissing: leaking heat exchanger or boiling of the boiler. Model hsg 100sd. In standstill, the pressure is 1.8 bar, and during operation (heating or DHW), the pressure drops to 1.3 bar. Is it okay? It's quite normal. Up to 0.5 drop at startup is allowed. The Gidrost boiler is in operation. When hot water is turned on, the batteries begin to warm up, although the heating of the batteries is turned off. Why is this happening? The three-way valve may be defective. We recommend calling a service technician. I bought a second boiler, Hydrosta HSD-160SD, for heating a bath. When connected, after 40 minutes, when all modes were tested, the device was locked. Error E5, abnormal burner flame, flame failure. I think I'm thinking about the gas pressure. The diameter of the hole for the gas-carrying pipe is 10 mm. It seems that the appearance of the flame is also normal. After calling the service, I realized that you can twist the variable resistors on the board.True, I didn’t speak personally. It is clear that the "low gas pressure" needs to be corrected. True, there is still such a cunning button - "gas pressure device". It is clear that to twist to the side less, and then press the button, but how long to hold? It is necessary to look at the moment of ignition. It is possible that only part of the burner lights up, which gives the e5 error. It is necessary to do a normal commissioning. Well, a wrong chimney can give the same error. And a dirty fan. The wall-mounted boiler of Hydrosta HSG-200SD is in operation. Over the weekend, I reworked the chimney system. Previously, the outlet of the combustion products was in the chimney for the gas water heater, I redid it through the wall onto the balcony using wall slitting, corrugation and insulation. In some places it was necessary to digest the propylene heating pipes, since they were in the path of the installed chimney corrugation. I cut them open, digested and then bleed the air just above the weld. The unit worked with the new chimney for two days. An unpleasant thing happened last night: hot water dripped from it and a puddle formed under it. I opened the front cover to see where it was leaking from. The whole bottom was in water. At first it seemed that it was oozing from under the hose connection, but then, looking closely, I realized that it was oozing from under the red air duct valve. I understand little about Khudrost's cauldrons. For the entire time of use, I only pumped up the expansion tank with air (somewhere this spring) and here it is. My first thought is that I made something with a new chimney, I removed the chimney pipe, shone a flashlight inside - it seems like it’s not jammed anywhere (it could get jammed during installation), and it doesn’t show the error “the chimney is clogged”. Works and oozes. The only thing I could do yesterday was to remove the filter mesh from the unit, the filter was, in general, not clogged with anything, but I just in case rinsed it and cleaned it with soap. Then he put it back in place. I opened the taps, took water into the system and then looked at what was running from under the red valve of the air duct (on the valve there is a key for a flat screwdriver, what kind of valve it is - I don't know at all, yesterday I saw it for the first time, today I found it to be some kind of air duct) ... After a couple of minutes, the leak disappeared by itself, I don't remember what I did, but the unit worked all night today, and there was no leak. Why could there be a leak? I didn’t bleed all the air from the heating system after welding the pipes, I accidentally “digested” the passage hole in the pipe. The pressure in the expansion tank has dropped again, or maybe the chimney has some kind of indirect effect? According to the idea, remove, disassemble, flush the air vent. Remove the air vent, rinse and replace. If that doesn't work, buy any 1/2 ″ male from a plumbing store and install it instead. A Gidrost gas boiler has been installed, it has been operating for 3 years, there were no problems, but recently they began to notice the smell of gas. We changed the gas hose to a metal one, but still there is a smell at the junction with the device. Was washed out and there was a bubble on the bolt, which is screwed into the gas valve (gas inlet into the apparatus). The question is what kind of bolt it is, what functions does it have, it just twists out. How to eliminate the gas outlet through it, it is screwed in to the end, does not help? It is not very clear which bolt we are talking about. There are 4 screws that secure the valve, twisted from the bottom up - there can be no leakage from them, but there is a screw - a plug on the gas pressure measuring point (below the boiler it is screwed into the tide horizontally from you to the wall) - there it can. It is corrected elementarily by replacing the seal ring. The Hydrosta HSG-200SD boiler has been operating for the 4th season. And just recently I noticed a little noise from it. He took off the front panel, listened - the pump was making noise, noise in the form of a kind of slight vibration, I don't even know what to compare with. What kind of sound could it be? Confused by the fact that the pump runs constantly, does not turn off at all, is this normal? Maybe before it also always worked, but I did not pay attention to it (there was no extraneous noise). Tomorrow I want to check the pressure in the expansion tank, I think it has nothing to do with the pump noise, but I'll check it anyway.If by the temperature of the coolant, then it is normal, if by air, then it should stop.

___________________________________________________________________________________________

___________________________________________________________________________________________

Repair of gas boilers AOGV Borino, ZhMZ, Siberia, Alpha Calor, Thermotechnik. Adjustment of gas automatics Eurosit 630. Replacement of the thermocouple and maintenance of the ignition burner.

Malfunctions and repairs of Baxi boilers Models Luna, Luna 3 Comfort, Luna Duo Tec (F / Fi). Double-circuit, turbocharged. Recommendations for eliminating errors and malfunctions. Settings and adjustment of operating modes.

Gas heating boilers Bosch Models ZWC, ZSA, ZSC, ZWR, Gaz 5000, Gaz 3000 W ZW, WBN 6000. Wall-mounted, double-circuit. Repairs, adjustments and malfunctions. Options for setting functions and modes.

Repair recommendation Navien Models Deluxe Coaxial, Deluxe Plus, GA. Errors and malfunctions. Work with remote control Ksital. System control. Setting work on temperature and pressure.

Floor standing boilers Buderus Repair of Logano G124, G125, G215, G234, G334 models. Breakdowns and malfunctions. Operation with Logomatic control system and indirect heating boiler. Modes and functions.

Operation of Vilant boilers Turbotec Atmotec pro / plus VU / VUW INT models. Components and work functions. Adjustment programs. Gas system. Installation and assembly. Maintenance and prevention.

Floor standing boilers Protherm Repair of the Bear models KLOM, KLZ, TLO, PLO with a capacity of 20 to 50 kW. Breakdowns and malfunctions. Operation, maintenance. Recommendations for setting operating parameters.

Lemax - repair and settings Models of gas floor boilers Premium, Leader, Patriot. Performance characteristics. Prime, Wise models. Adjustment of automatic equipment Eurosit, Minisit, Sit Nova. Solid fuel boilers Forward.

Wall-mounted coppers of Protherm Repair of the Panther, Cheetah, Jaguar, Lynx, Leopard models. Breakdowns and malfunctions. Operation and service. Recommendations for adjusting operating modes.

Beretta - repair and adjustment Repair and operation of boilers Ciao, City, Novella, Exclusive. Wall and floor models. Malfunctions and error codes. Working functions and setting of service modes. Maintenance.

Boilers Teplodar Kupper PRO Operation and adjustment of solid fuel boilers with a capacity of 22, 28, 36 kW. Installation of an automatic pellet burner APG-25, 36, 42. Settings of operating modes.

Repair of gas boilers Oasis Models of wall-mounted boilers ZRT, ZRN, BM. Malfunctions and error codes. Troubleshooting tips. Operating modes and setting of service parameters. Maintenance.

Heating boilers Alfatherm Description of Beta floor-standing boilers and Sigma wall-hung gas boilers. Malfunctions and error codes. Repair and troubleshooting questions. Basic maintenance work.

Wolf - malfunctions and repairs The Wolf boiler is installed. I noticed that over time, the pressure in it gradually decreases (by about 1 in 2 days). I checked all the pipes for leaks but found nothing. What else to check?

Gas boilers Junkers After 7 years of operation, the gas boiler Junkers ZW-23-KE has the following problems. When DHW starts working, it either turns off or stops working ...

Repair of boilers Neva Lux Neva Lux 8224 (Baltgaz), discovered the following problem: the post-circulation pump does not turn off, no matter what the temperature is. To make sure that this is so, he raised the temperature in ...